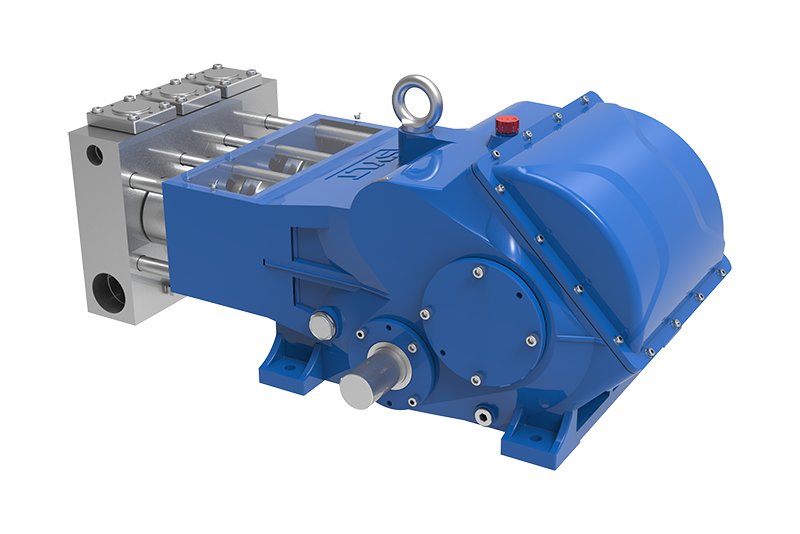

Durable plunger high pressure pumps are essential components in the realm of industrial equipment, especially within the category of pumps and vacuum devices. These pumps are specifically designed to handle high pressure and provide consistent performance across a range of challenging applications. Understanding their functionality and advantages can aid industries in selecting the right pump for their specific needs.

At the core of a plunger pump’s operation is its mechanism, which utilizes a plunger to move liquid through a cylindrical chamber. This design allows for the generation of high pressure, making plunger pumps ideal for applications that require a strong and reliable fluid transfer. The durable design of these pumps ensures that they can withstand the rigorous demands of high-pressure operations, making them suitable for tasks such as water blasting, chemical injection, and oil recovery.

One of the primary benefits of durable plunger high pressure pumps is their efficiency in transferring fluids at elevated pressures. This capability not only enhances productivity but also reduces operational costs in the long run. Industries like manufacturing, agriculture, and oil and gas frequently rely on these pumps to facilitate processes that require high-pressure liquid transfer, thereby improving their overall operational efficiency.

Another significant advantage is the longevity of these pumps. Because they are built with robust materials, durable plunger pumps are less prone to wear and tear compared to other pump types. This resilience translates to less downtime and lower maintenance costs, an essential factor for industrial operations where time is money. Regular maintenance, however, is crucial to ensuring these pumps operate at peak performance levels.

In terms of versatility, durable plunger high pressure pumps can handle various types of fluids, including water, oils, and chemicals. This flexibility allows them to be employed in diverse industries, ranging from construction to pharmaceuticals. Their ability to adjust to different fluid viscosities and characteristics makes them a valuable asset for companies that require a versatile pumping solution.

Moreover, advancements in technology have led to the development of more efficient and environmentally friendly plunger pumps. Modern designs incorporate features that reduce energy consumption and limit environmental impact, aligning with the growing emphasis on sustainability in industrial operations.

In summary, durable plunger high pressure pumps are a cornerstone of industrial equipment, providing reliable, efficient, and long-lasting performance in demanding applications. Understanding their functionality and benefits can significantly enhance operational efficiencies for businesses across various sectors. As industries evolve, the significance of these pumps will continue to grow, underscoring their vital role in modern industrial processes.

The 17th China International Powder Metallurgy and Hard Alloy Exhibition

The 2025 17th China International Powder Metallurgy and Hard Alloy Exhibition from March 10-12, 2025, at the Shanghai World Expo Exhibition and Convention Center, Hall H1, B425. We welcome guests to visit.

"Private custom" product design, reliable and durable finished products

"Private custom" like product design, reliable and durable finished products, professional and timely after-sales service. It is the "three basic concepts" that the company adheres to from the beginning until today ".

Experienced market research team, independent product development concept

We have experienced mature market research team, independent product research and development concept, professional design and manufacturing technology so that the company's products can be adjusted according to the specific requirements of customers timely design