The high-pressure pump-driven spray dust suppression system efficiently captures dust by creating a fine mist of water, significantly improving the working environment in coal mines. The following table summarizes its key applications and features in coal mining settings:

| Application scenarios | Implementation Methods and Features | Dust reduction effect reference |

|---|---|---|

| Coal Mining Machine Cutting Unit | Install high-pressure nozzles near the shearer's cutting drum, Directly cover the dust source . Water pressure is typically increased to 10-20MPa , forming fine water mist. | According to the application report, the overall dust removal efficiency has been significantly improved. |

| Excavation working face | Primarily equips continuous mining machines or roadheaders with high-pressure external spray systems. By optimizing nozzles and installing an additional booster pump, a sealed mist curtain is formed. | Research shows that the settling rate of respirable dust ≥72.5% 。 |

| Transportation and Transfer Point | Set up high-pressure spray curtains at material discharge points such as belt conveyor heads and chutes. | It can effectively suppress coal dust from being dispersed. |

? The advantages of high-pressure mist dust suppression

Compared to traditional low-pressure water spraying for dust suppression, high-pressure misting technology offers several distinct advantages:

High dust suppression efficiency : The core advantage lies in addressing the most significant threats Respirable dust It has a remarkable capture effect.

Water-saving and environmentally friendly : The water mist particles are extremely fine, Low water consumption , which prevents water accumulation and waste of water resources in the work area, while also helping to improve the working environment.

Combines cooling and gas management potential : Water mist evaporates by absorbing heat, providing a cooling effect in summer. Auxiliary cooling Effectiveness. Some technologies also mention that high-pressure spraying has Auxiliary gas dispersal The role of it.

? System Architecture and Key Technologies

A complete high-pressure mist dust suppression system typically includes:

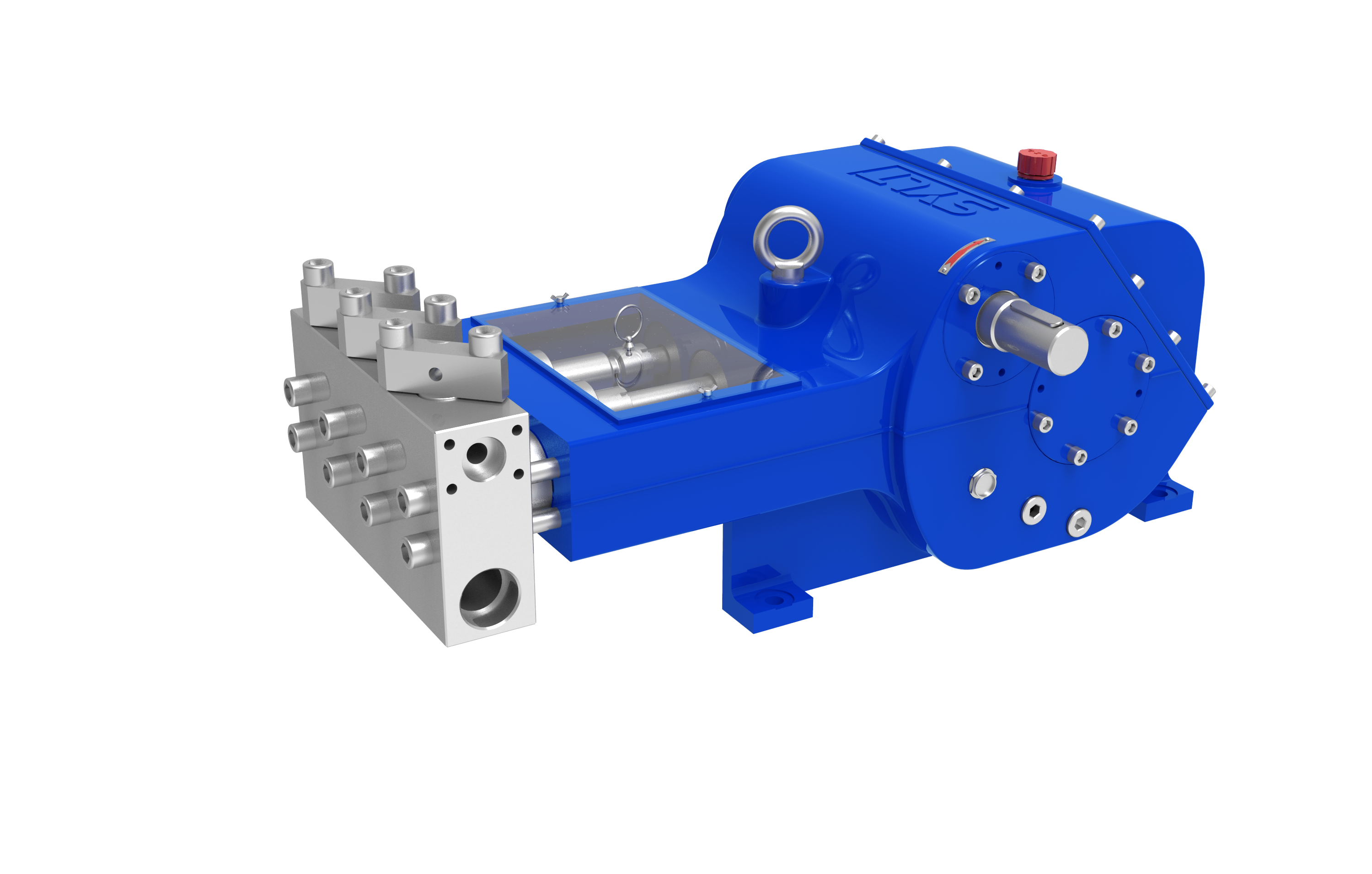

High-Pressure Pump Station : The core power source, providing a stable high-pressure water supply.

Precision filtration device : Prevent nozzle clogging and ensure stable system operation.

High-pressure pipelines and dedicated nozzles : Delivers high-pressure water and achieves precise atomization.

Automatic Control System : Achieve automated control of the spray.

In practical applications, it's important to note Water Quality Treatment (To prevent nozzle clogging), System Pressure Optimization (Balancing dust suppression effectiveness with energy consumption and equipment lifespan) and Reliability of equipment under harsh operating conditions And other issues 。

Overall, the high-pressure pump spray dust suppression technology effectively addresses the challenging issue of dust control in coal mining operations through innovative physical mechanisms, making it one of the key technologies for ensuring safe production and protecting miners' health.

We hope the information above helps you better understand the application of high-pressure pumps in dust suppression at coal mines. If you have more specific questions about a particular application scenario or equipment, I’d be happy to provide further analysis.

The 17th China International Powder Metallurgy and Hard Alloy Exhibition

The 2025 17th China International Powder Metallurgy and Hard Alloy Exhibition from March 10-12, 2025, at the Shanghai World Expo Exhibition and Convention Center, Hall H1, B425. We welcome guests to visit.

"Private custom" product design, reliable and durable finished products

"Private custom" like product design, reliable and durable finished products, professional and timely after-sales service. It is the "three basic concepts" that the company adheres to from the beginning until today ".

Experienced market research team, independent product development concept

We have experienced mature market research team, independent product research and development concept, professional design and manufacturing technology so that the company's products can be adjusted according to the specific requirements of customers timely design