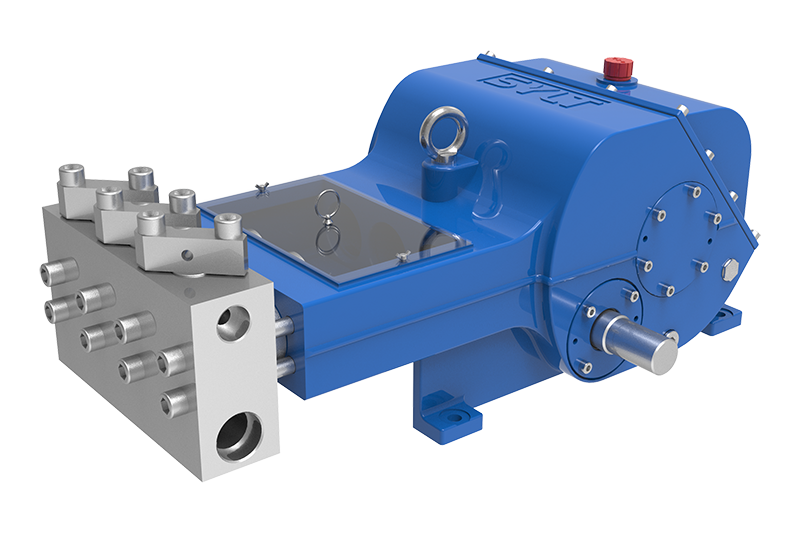

One of the primary functions of high pressure pumps is to transport fluids at pressures exceeding 150 psi. They are commonly used in applications that require high flow rates and reliable performance. For instance, in the oil and gas industry, these pumps facilitate the extraction and transportation of crude oil and natural gas. In the chemical industry, they are essential for mixing and transferring hazardous chemicals safely. Additionally, in water treatment facilities, high pressure pumps are employed to ensure efficient operation of filtration systems.

Quality high pressure pumps come in various designs, including positive displacement and dynamic pumps, each suited for different operational needs. Positive displacement pumps, such as gear pumps and diaphragm pumps, are ideal for applications requiring precise flow control. On the other hand, dynamic pumps, like centrifugal pumps, are more suitable for applications with higher flow rates but lower pressure requirements. Understanding these differences can aid professionals in selecting the right pump for their specific application.

Moreover, the efficiency of high pressure pumps is influenced by several factors, including material selection, pump design, and maintenance practices. High-quality pumps are often constructed from corrosion-resistant materials, enabling them to withstand harsh operating conditions and extend service life. Regular maintenance, including routine inspections and timely repairs, is essential to ensure optimal performance and prevent costly downtime.

In addition to performance, energy efficiency is a crucial consideration when selecting quality high pressure pumps. Advanced pump technologies, such as variable frequency drives (VFDs), can enhance energy efficiency by allowing operators to adjust pump speed according to demand, leading to significant cost savings over time.

In conclusion, quality high pressure pumps play a critical role in a variety of industrial processes, providing the necessary pressure to transport fluids effectively. By understanding the various types, applications, and maintenance needs of these pumps, professionals can enhance operational efficiency and ensure the longevity of their equipment. When selecting a high pressure pump, it is essential to consider not only performance but also the potential for energy savings and the importance of regular maintenance to achieve optimal results.

The 17th China International Powder Metallurgy and Hard Alloy Exhibition

The 2025 17th China International Powder Metallurgy and Hard Alloy Exhibition from March 10-12, 2025, at the Shanghai World Expo Exhibition and Convention Center, Hall H1, B425. We welcome guests to visit.

"Private custom" product design, reliable and durable finished products

"Private custom" like product design, reliable and durable finished products, professional and timely after-sales service. It is the "three basic concepts" that the company adheres to from the beginning until today ".

Experienced market research team, independent product development concept

We have experienced mature market research team, independent product research and development concept, professional design and manufacturing technology so that the company's products can be adjusted according to the specific requirements of customers timely design