Here is a core introduction of the high-pressure pump in this application:

I. Core Role: The Proactive "Surgical Scalpel" and "Safety Valve"

In coal mining, the hard roof above the working face—such as sandstone—does not collapse promptly as coal is extracted, instead forming a large-area "overhanging roof." This overhanging roof hangs like the Sword of Damocles, accumulating tremendous energy. Should it suddenly give way, it could easily trigger Rockburst (mine earthquake) 、 Gas Outburst Such catastrophic accidents.

The core function of the high-pressure pump unit is to serve as a... The proactive "surgical scalpel" , using directional hydraulic fracturing technology, precisely and controllably—either before or after coal mining— Pre-splitting Roof Rock Stratum , cutting it into manageable smaller pieces. This is equivalent to installing a controllable system for roof pressure. "Safety Valve" 。

Its main purpose:

Pressure relief : Artificially releasing the stress accumulated in the roof prevents an instantaneous energy burst.

Guide the collapse : Ensure the roof can collapse in a planned, phased, and orderly manner, eliminating the threat of large-scale unsupported roof areas.

Gas Management : The fracture network created by hydraulic fracturing serves as a pathway for gas to escape, facilitating extraction and fundamentally reducing the risks of gas over-limitation and outbursts.

Reduce mine tremors : By proactively releasing energy, we can reduce the occurrence of large-scale, destructive mine earthquakes.

II. System Composition and Workflow

This is a complete system—its heart is the high-pressure pump.

System's main components:

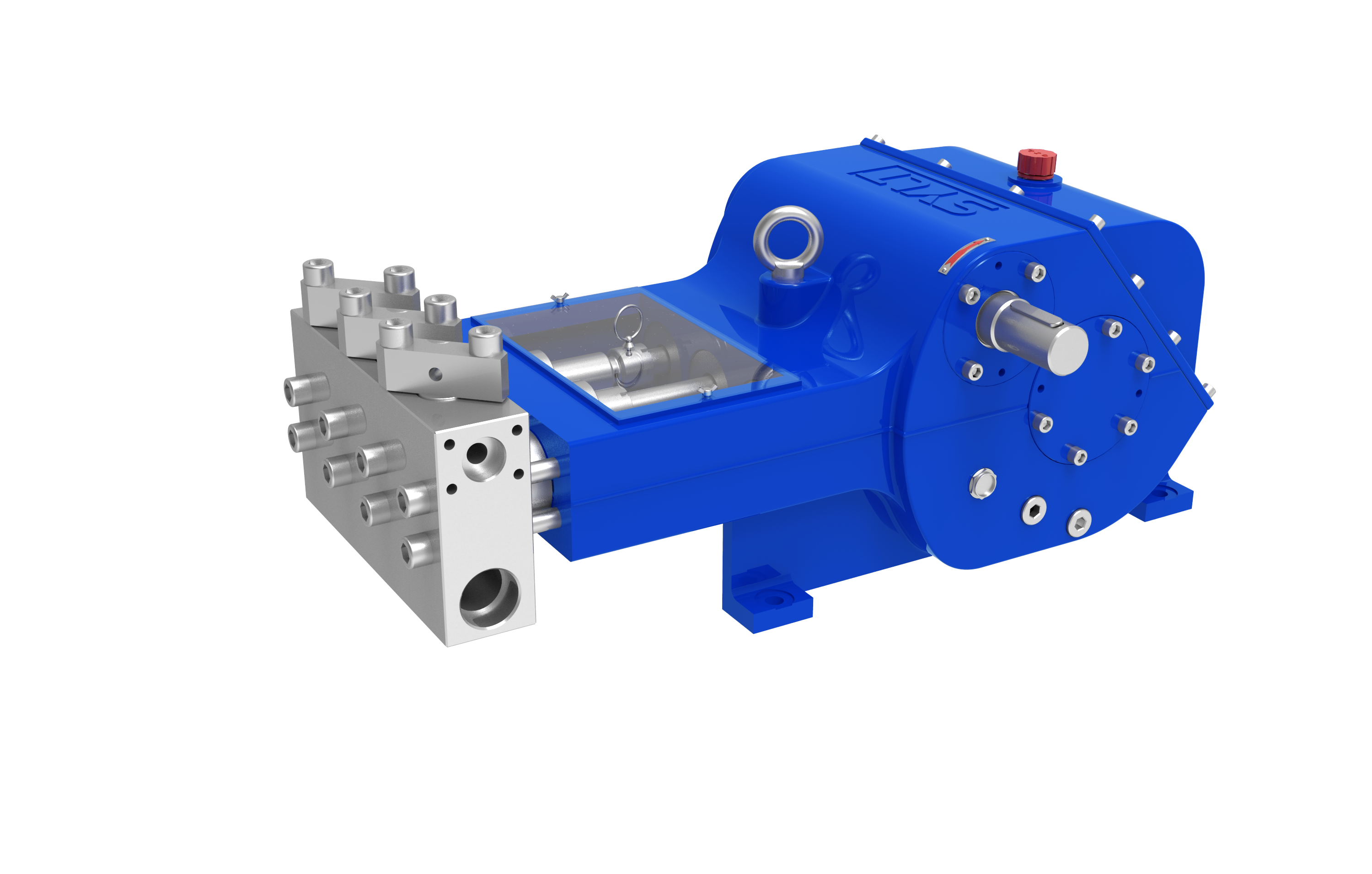

High-pressure pump unit : The power core generates ultra-high pressure.

Explosion-proof Power Source : Electric motor or explosion-proof diesel engine.

Control System : Integrating pressure, flow sensors, and a PLC to achieve precise control and remote operation.

High-pressure Piping and Valve Assembly : Delivers high-pressure water and includes protective devices such as safety valves and relief valves.

Dedicated Hole-Sealing Device (Fracturing Tool) : The key execution component seals the hole at a designated location, creating a high-pressure chamber.

Water tank : Provide a water source.

Typical workflow:

Drilling : Drilling boreholes at a specific angle and depth into the roof plate within the tunnel.

Lower the sealing device : Insert the hole-plugging device into the predetermined drilling depth.

Sealing the holes : Activate the packer to cause it to expand, sealing off a section of the borehole and creating a closed-off fracture segment.

Water-flooding fracturing :

The high-pressure pump starts, injecting high-pressure water into the sealing section via the high-pressure pipeline.

The pump pressure continues to rise, and when the water pressure exceeds the tensile strength of the rock layer, the layer is "torn open," creating an initial fracture.

Continuous water injection causes the fractures to further propagate and extend along the weak planes of the rock layers, ultimately forming a complex fracture network.

Stabilized-pressure osmosis After cracks form, it is sometimes necessary to maintain a certain pressure to allow water to seep in, softening the rock mass and facilitating its subsequent collapse.

Pressure Relief and Withdrawal After fracking is completed, the system releases pressure, the packer contracts, and the equipment is retrieved.

III. Key Technical Requirements for High-Pressure Pump Units

Due to the unique characteristics of the underground coal mine environment, extremely stringent requirements are imposed:

| Project | Specific requirements and instructions |

|---|---|

| Work stress | Extremely high , usually at 50 - 150 MPa Within the specified range, it must be capable of delivering sufficient pressure to fracture even the hardest roof strata, such as sandstone. |

| Traffic | Moderate to high flow , sufficient flow is needed to quickly fill and widen the cracks. |

| 贰虫辫濒辞蝉颈辞苍-辫谤辞辞蹿特性 | Mandatory requirement The entire pump unit must be Mining explosion-proof type , and achieve Coal Safety Mark (MA Certification) , this is the bottom line for well-entry permits. |

| Reliability | The underground environment is harsh—characterized by dust, humidity, and vibrations—so equipment must be robust, durable, and designed for an extremely low failure rate. The core pump unit typically employs a mature and reliable three-plunger or five-plunger high-pressure pump. |

| Mobility | Usually designed as Caterpillar- or wheeled self-propelled equipment , with a compact structure that makes it easy to maneuver and deploy in narrow alleyways. |

| Automation and Security | Should possess Remote control Function that keeps operators away from hazardous areas; equipped with Automatic Pressure-Flow Regulation 、 Automatic overpressure relief 、 Real-time Monitoring and Recording of Operating Parameters Functions such as these ensure the process is controllable, safe, and traceable. |

IV. Key Considerations for Selection and Operation

Parameter Selection : Scientifically calculate the required pump unit's rated pressure and flow rate based on the lithology (strength, thickness, and joint development) of the target roof strata.

Certification is the prerequisite. : Non-mining explosion-proof equipment must never be used. . The equipment must bear a valid "MA" mark.

Automation Level : Prioritize selecting highly automated units, as they not only ensure personnel safety but also enhance the scientific rigor and repeatability of fracturing operations through precise data control.

Operational Safety :

During fracking operations, personnel are strictly prohibited from standing in front of equipment and pipelines.

Strictly enforce the underground gas inspection system.

Pipeline connections must be reliable and inspected regularly.

In summary , in coal mine roof fracture situations, the high-pressure pump unit is a set High-power, high-pressure, explosion-proof, and mobile Powerful safety equipment designed to proactively intervene through engineering, altering the physical structure and mechanical behavior of the roof—this is the key technological approach for addressing major roof safety hazards at their source.

The 17th China International Powder Metallurgy and Hard Alloy Exhibition

The 2025 17th China International Powder Metallurgy and Hard Alloy Exhibition from March 10-12, 2025, at the Shanghai World Expo Exhibition and Convention Center, Hall H1, B425. We welcome guests to visit.

"Private custom" product design, reliable and durable finished products

"Private custom" like product design, reliable and durable finished products, professional and timely after-sales service. It is the "three basic concepts" that the company adheres to from the beginning until today ".

Experienced market research team, independent product development concept

We have experienced mature market research team, independent product research and development concept, professional design and manufacturing technology so that the company's products can be adjusted according to the specific requirements of customers timely design