Overview: From Traditional Manual Work to Robotic Automation

Traditional ship cleaning—especially for the hull—heavily relies on manual high-pressure water gun operations, often requiring scaffolding or underwater work by divers. This approach, however, poses Low efficiency, high costs, significant safety risks, and substantial environmental pressures And many other issues.

The wall-climbing robot uses advanced adhesion technologies—such as magnetic or vacuum suction—to firmly attach itself to the ship’s hull surface. Equipped with cleaning tools like high-pressure water guns or brush systems, it performs automated or semi-automated operations, effectively addressing the pain points of conventional methods.

Main application scenarios of wall-climbing robots in ship cleaning

Hull Shell Cleaning

Removing marine organism attachments: This is the most critical need. Marine organisms such as barnacles and algae attach themselves to ship hulls, causing "biofouling," which significantly increases drag during navigation and leads to higher fuel consumption—up to 40% in some cases. Robots can efficiently remove these unwanted attachments.

Corrosion-Resistant Coating Maintenance: During the dry-dock overhaul, robots can be used to clean the ship's hull, preparing it for a new anti-corrosion coating.

Cleaning of large, enclosed compartments such as ballast tanks and cargo oil tanks

These compartments feature large internal spaces, complex structures, and harsh environments (which may contain hazardous gases), making manual cleaning extremely difficult and dangerous. Specialized explosion-proof and corrosion-resistant wall-climbing robots can enter the compartments to perform high-pressure water cleaning or drying operations.

Side cleaning of ships and vertical surface cleaning for ultra-large vessels

For giant container ships, LNG carriers, and other vessels with enormous hull areas, manual cleaning is extremely time-consuming. However, multiple robots working in coordination can significantly reduce the cleaning time.

The core technological components of the wall-climbing robot cleaning system

Adsorption Technology

Magnetic Adsorption: Primarily used for steel hulls, it generates adhesive force via strong permanent magnets or electromagnets. With its simple structure, it is safe and reliable—and currently the most mainstream technology.

Vacuum suction: Suitable for surfaces of any material (such as fiberglass hulls or painted surfaces). Negative pressure is generated either by a vacuum pump or via the Venturi effect. While it demands higher surface flatness, its applicability is broader.

Method of movement

Wheeled: Fast-moving and suitable for surfaces that are either flat or have only slight curvature.

Caterpillar-type: It boasts strong obstacle-crossing ability, better adaptability to complex surfaces (such as rivets and welds), and more stable adhesion.

Cleaning system

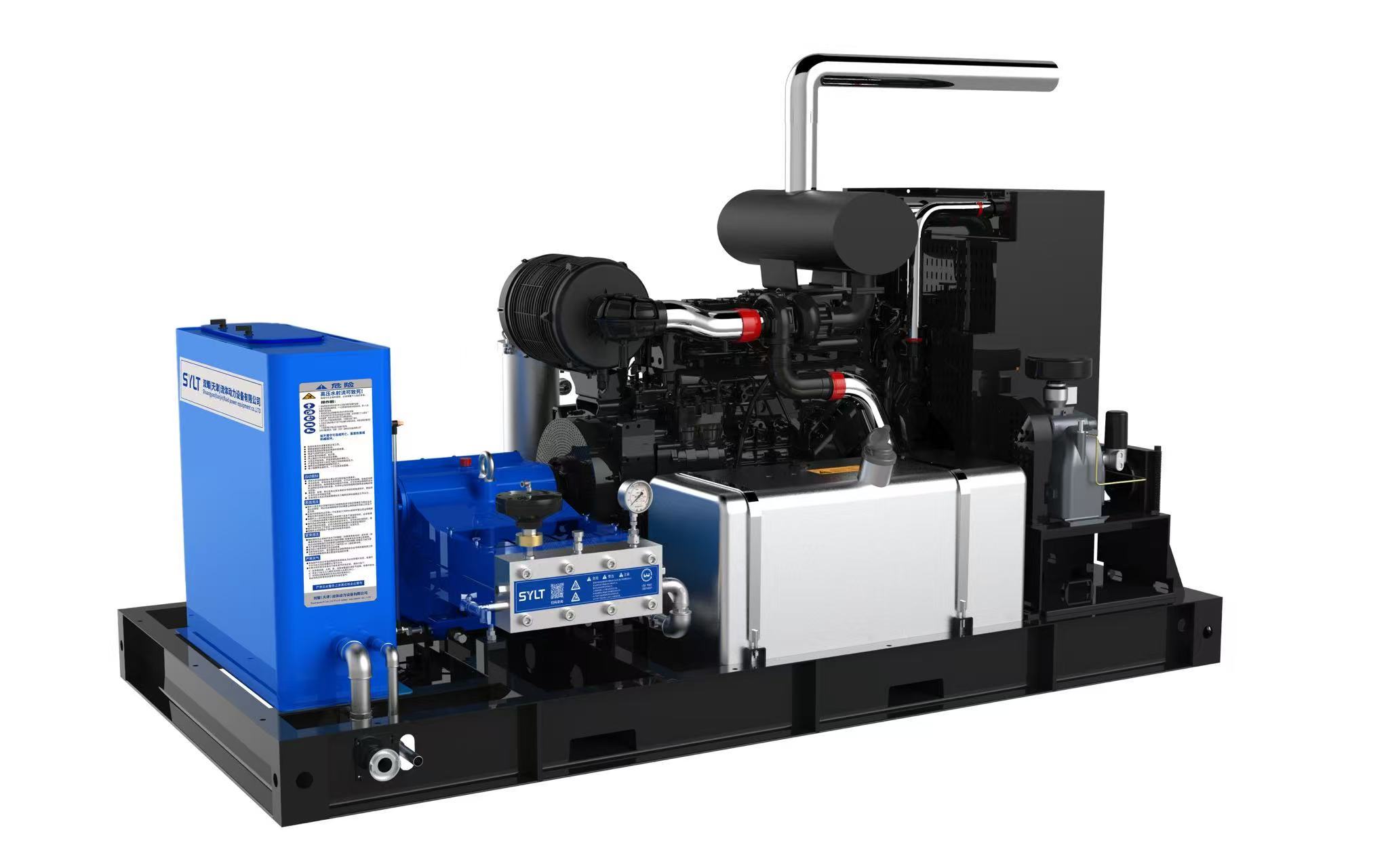

High-pressure water jet: The core cleaning method uses a high-pressure water pump to generate extremely fine, high-pressure water jets that forcefully dislodge and remove dirt.

Rotating brush disc: When used in combination with high-pressure water, it enhances the cleaning effect through physical friction, especially effective against stubborn biological deposits.

Water Recycling and Treatment System (Optional): Advanced systems will be equipped with vacuum systems to recover wastewater and removed contaminants generated during cleaning, enabling centralized treatment and achieving "zero emissions," thereby complying with environmental regulations.

Navigation and Control System

Remote control: The operator controls the robot from the shore or on deck using a remote control and video feedback.

Semi-autonomous / Fully autonomous: The robot autonomously plans its cleaning path using pre-programmed routes or sensors such as LiDAR and visual cameras, ensuring complete coverage of the vessel's entire surface—leaving the operator to simply monitor the process.

Significant advantages over traditional manual cleaning

| Characteristics | Wall-climbing robot | Traditional manual cleaning |

|---|---|---|

| Security | Extremely high No need for高空作业 or diving, eliminating risks such as falls and drowning. | High risk Involving high-altitude, confined space, and underwater operations, the risk of accidents is significant. |

| Efficiency | High It can operate continuously for 24 hours, with multiple robots working collaboratively—resulting in a cleaning speed 3 to 5 times faster than manual labor. | Low Due to weather conditions and limitations in personnel stamina, progress is slow. |

| Cost | Low long-term costs Although the equipment requires an initial investment, it significantly saves on labor, insurance, and time costs. | High explicit and implicit costs Including labor costs, equipment rental, insurance, and lost revenue due to vessel停航, among others. |

| Cleaning quality | Stable and uniform Robots operate according to preset parameters, preventing uneven cleaning or damage to the ship's hull caused by human factors. | High volatility Relying on workers' skills and sense of responsibility. |

| Environmental friendliness | Excellent . The system can integrate wastewater recycling, preventing wastewater containing heavy-metal-based anti-fouling paints from being directly discharged into the port. | Poor Wastewater and contaminants are directly discharged into the water, causing environmental pollution. |

| Data Recording | Support It can record the cleaning process and capture images of the hull surface condition, providing data support for ship maintenance. | Difficulty It's difficult to quantify and record. |

Development Trends

Development trend:

Intelligence and Autonomy: By integrating AI-powered visual recognition, the robot can automatically identify the degree and type of contamination, then adjust its cleaning strategy accordingly.

Cluster Collaboration: Multiple small robots are released from the "mother ship" and work together like a swarm to efficiently clean the massive hull.

Greenwashing: Develop more environmentally friendly cleaning technologies such as lasers and ultrasonic waves, and enhance wastewater recycling rates.

Multifunctionality: In addition to cleaning, the robot can also integrate inspection functions (such as thickness measurement and crack detection), enabling an integrated "cleaning + inspection" solution.

Conclusion

The application of wall-climbing robots in ship cleaning serves as a prime example of how smart equipment is empowering traditional industries. By fundamentally enhancing operational safety, efficiency, and environmental sustainability, these robots are driving the ship maintenance sector toward automation and digitalization. As the technology continues to mature and costs gradually decline, wall-climbing robots are poised to become standard equipment at major ports and shipyards worldwide.

The 17th China International Powder Metallurgy and Hard Alloy Exhibition

The 2025 17th China International Powder Metallurgy and Hard Alloy Exhibition from March 10-12, 2025, at the Shanghai World Expo Exhibition and Convention Center, Hall H1, B425. We welcome guests to visit.

"Private custom" product design, reliable and durable finished products

"Private custom" like product design, reliable and durable finished products, professional and timely after-sales service. It is the "three basic concepts" that the company adheres to from the beginning until today ".

Experienced market research team, independent product development concept

We have experienced mature market research team, independent product research and development concept, professional design and manufacturing technology so that the company's products can be adjusted according to the specific requirements of customers timely design