Maximize Efficiency with a China Water Jet Cleaning Machine

Table of Contents

- 1. Introduction to Water Jet Cleaning Technology

- 2. Benefits of Using China Water Jet Cleaning Machines

- 3. Applications of Water Jet Cleaning in Various Industries

- 4. How to Select the Right Water Jet Cleaning Machine

- 5. Maximizing Operational Efficiency with Water Jet Cleaning

- 6. Maintenance Tips for Long-lasting Performance

- 7. Real-World Case Studies: Success Stories

- 8. Frequently Asked Questions About Water Jet Cleaning Machines

- 9. Conclusion: The Future of Cleaning with Water Jet Technology

1. Introduction to Water Jet Cleaning Technology

In the modern industrial landscape, efficiency and effectiveness in cleaning operations are paramount. Traditional cleaning methods often fall short, leading to the rise of innovative technologies like the **China Water Jet Cleaning Machine**. This state-of-the-art equipment uses high-pressure water jets to remove contaminants, making it an invaluable asset for various industries. As we delve deeper into this technology, we will explore its advantages, applications, and how it can revolutionize your cleaning processes.

2. Benefits of Using China Water Jet Cleaning Machines

Water jet cleaning machines offer a myriad of benefits that set them apart from conventional cleaning methods. Some of the key benefits include:

2.1 Environmentally Friendly

Utilizing **high-pressure water jets** reduces the need for harsh chemicals, making the cleaning process more environmentally friendly. This not only protects the environment but also enhances the safety of workers.

2.2 Cost-Effective

Investing in a China water jet cleaning machine can lead to significant cost savings. These machines are designed for durability and efficiency, minimizing maintenance costs and downtime.

2.3 Versatility

These machines can effectively clean a wide range of surfaces and materials, including metal, concrete, and glass. Their versatility makes them suitable for various applications, from industrial cleaning to delicate surface restoration.

3. Applications of Water Jet Cleaning in Various Industries

Understanding the diverse applications of water jet cleaning machines is crucial for maximizing their potential. Here are some industries where these machines excel:

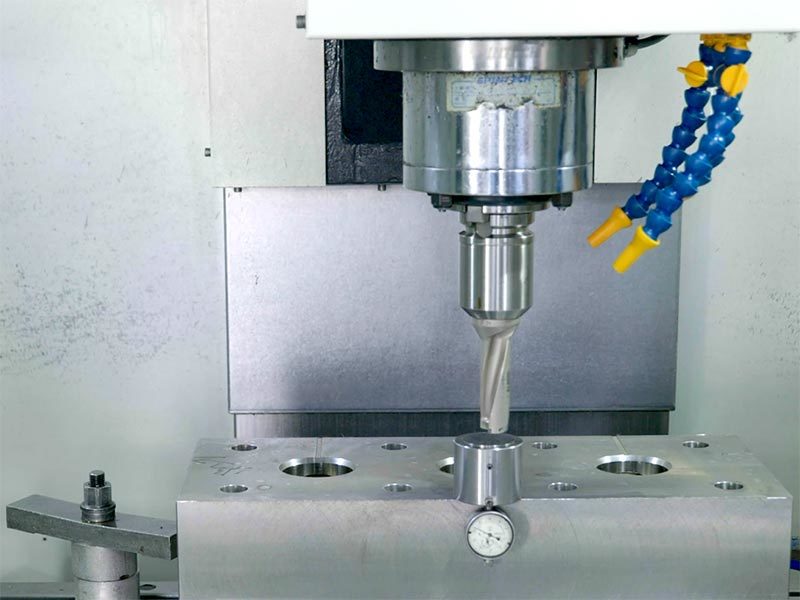

3.1 Manufacturing Industry

In manufacturing, water jet cleaning machines are used to remove grease, oil, and metal shavings from machinery. This ensures equipment operates efficiently and prolongs its lifespan.

3.2 Construction and Demolition

Water jet cleaning is invaluable in construction and demolition, where it is used to clean surfaces and remove debris without damaging the underlying material.

3.3 Food Processing

In the food industry, maintaining hygiene is critical. Water jet cleaning machines effectively sanitize equipment and surfaces, ensuring compliance with health regulations.

3.4 Automotive Sector

Automotive manufacturers leverage water jet cleaning to remove paint and rust from vehicle parts, preparing them for painting and assembly.

4. How to Select the Right Water Jet Cleaning Machine

Choosing the right water jet cleaning machine involves considering several factors:

4.1 Pressure and Flow Rate

The cleaning power of the machine largely depends on its pressure and flow rate. Higher pressure is required for tougher contaminants, while flow rate affects the speed of cleaning.

4.2 Mobility

Consider the mobility of the machine. Some models are portable, while others are designed for stationary use. Choose a machine that fits your operational needs.

4.3 Nozzle Types

Different nozzle types can significantly affect the cleaning process. Ensure the machine you select has a range of nozzles for various applications.

5. Maximizing Operational Efficiency with Water Jet Cleaning

To fully harness the efficiency of a water jet cleaning machine, implementing optimal operational practices is essential.

5.1 Proper Training for Operators

Investing in training for operators ensures that they understand how to use the equipment effectively and safely. Proper training can significantly enhance cleaning results.

5.2 Regular Maintenance Checks

Conducting regular maintenance checks ensures that the machine operates at peak efficiency. This includes inspecting hoses, nozzles, and fittings for wear and tear.

5.3 Optimizing Cleaning Solutions

In some cases, combining water jet cleaning with eco-friendly cleaning solutions can improve results without compromising safety.

6. Maintenance Tips for Long-lasting Performance

Regular maintenance extends the lifespan of your water jet cleaning machine and ensures consistent performance. Here are some essential maintenance tips:

6.1 Daily Inspections

Conduct daily checks for leaks, wear, and other issues. Identifying problems early can prevent costly repairs.

6.2 Cleaning Filters and Nozzles

Regularly clean and replace filters and nozzles to maintain optimal performance and prevent clogging.

6.3 Seasonal Maintenance

Perform comprehensive inspections and servicing at least twice a year to address any major issues and keep the machine in top condition.

7. Real-World Case Studies: Success Stories

Examining successful case studies can provide insight into how water jet cleaning machines have transformed operations in various industries.

7.1 Case Study: Manufacturing Plant Efficiency

A manufacturing plant reported a 30% increase in productivity after implementing a water jet cleaning machine, allowing for quicker turnaround times on equipment maintenance.

7.2 Case Study: Automotive Restoration Success

An automotive restoration shop utilized water jet cleaning for rust removal, resulting in a 50% reduction in labor time and an increase in customer satisfaction.

8. Frequently Asked Questions About Water Jet Cleaning Machines

8.1 What is the average lifespan of a water jet cleaning machine?

The average lifespan can vary, but with proper maintenance, these machines can last over 10 years.

8.2 Are water jet cleaning machines safe to use?

Yes, when operated correctly, they are safe. Operators should follow safety guidelines and wear appropriate protective gear.

8.3 Can I use my water jet cleaning machine on delicate surfaces?

Yes, with the right nozzle and pressure adjustments, water jet machines can be used on delicate surfaces without causing damage.

8.4 How much water does a water jet cleaning machine use?

Water consumption depends on the machine's specifications, but many are designed to be efficient and use less water than traditional cleaning methods.

8.5 Is training necessary for operating a water jet cleaning machine?

Yes, training is essential for ensuring safe and efficient operation, as well as for understanding the machine’s features and capabilities.

9. Conclusion: The Future of Cleaning with Water Jet Technology

The **China Water Jet Cleaning Machine** represents a significant advancement in industrial cleaning technology. Its ability to combine efficiency, cost-effectiveness, and environmental friendliness makes it an ideal choice for various sectors. By understanding its benefits and applications, selecting the right machine, and maintaining it properly, businesses can maximize operational efficiency and achieve superior cleaning results. As industries continue to evolve, embracing innovative cleaning technologies like water jet systems will be crucial for maintaining competitiveness and sustainability in the market.

The 17th China International Powder Metallurgy and Hard Alloy Exhibition

The 2025 17th China International Powder Metallurgy and Hard Alloy Exhibition from March 10-12, 2025, at the Shanghai World Expo Exhibition and Convention Center, Hall H1, B425. We welcome guests to visit.

"Private custom" product design, reliable and durable finished products

"Private custom" like product design, reliable and durable finished products, professional and timely after-sales service. It is the "three basic concepts" that the company adheres to from the beginning until today ".

Experienced market research team, independent product development concept

We have experienced mature market research team, independent product research and development concept, professional design and manufacturing technology so that the company's products can be adjusted according to the specific requirements of customers timely design