The Ultimate Guide to Selecting a Quality High Pressure Booster Pump

Table of Contents

- 1. Introduction to High Pressure Booster Pumps

- 2. Understanding High Pressure Booster Pumps: What You Need to Know

- 3. Types of High Pressure Booster Pumps

- 4. Key Specifications to Consider

- 5. Applications of High Pressure Booster Pumps

- 6. Common Mistakes to Avoid When Selecting a Booster Pump

- 7. Maintenance Tips for High Pressure Booster Pumps

- 8. Frequently Asked Questions (FAQs)

- 9. Conclusion

1. Introduction to High Pressure Booster Pumps

High pressure booster pumps play a crucial role in various industrial applications by increasing the pressure of liquids or gases within a system. These pumps are designed to enhance performance, ensuring a consistent flow rate and pressure for a variety of processes. As industries evolve, the demand for reliable and efficient booster pumps has surged, making it essential to understand the factors that contribute to selecting the right equipment.

2. Understanding High Pressure Booster Pumps: What You Need to Know

High pressure booster pumps are specialized devices that elevate the pressure of fluids, ensuring optimal performance in systems requiring substantial pressure levels. They are commonly used in applications such as water supply systems, irrigation, fire fighting systems, and industrial processes.

**Key Characteristics:**

- **Pressure Rating:** The maximum pressure the pump can generate.

- **Flow Rate:** The volume of fluid the pump can move within a specified timeframe.

- **Power Requirements:** The energy needed to operate the pump effectively.

By understanding these characteristics, one can make a more informed decision when selecting a high pressure booster pump.

3. Types of High Pressure Booster Pumps

Choosing the right type of booster pump is critical for achieving the desired performance. Here are the most common types of high pressure booster pumps:

Centrifugal High Pressure Booster Pumps

Centrifugal pumps utilize rotational energy to increase fluid pressure. They are ideal for applications requiring high flow rates and moderate pressure levels.

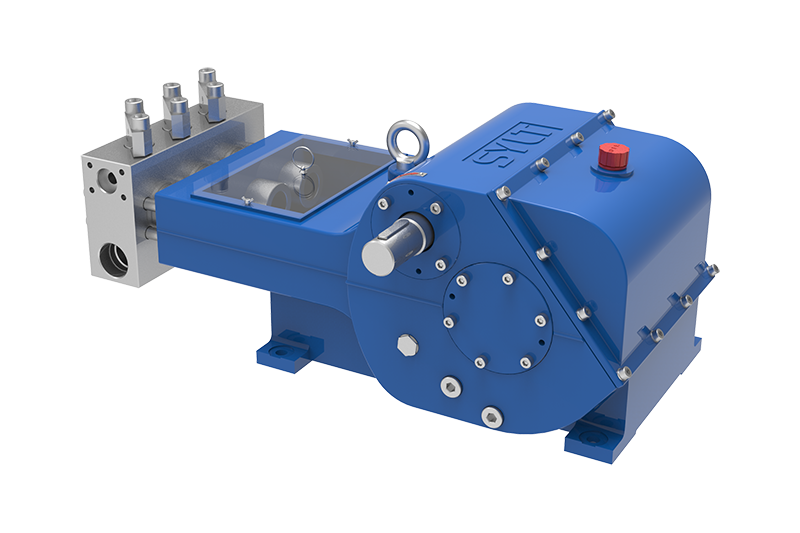

Positive Displacement Pumps

These pumps move fluid by trapping a fixed amount and forcing it into the discharge pipe. They are suitable for high-viscosity liquids and applications requiring high pressure.

Multistage Pumps

Multistage pumps consist of several impellers, allowing them to achieve high pressure levels. They are commonly used in water treatment, irrigation, and HVAC systems.

Submersible Pumps

Submersible pumps are designed to operate underwater, making them perfect for wells and boreholes where high pressure is necessary.

4. Key Specifications to Consider

When selecting a high pressure booster pump, several specifications must be evaluated to ensure compatibility with your specific needs.

Flow Rate

Understanding the required flow rate is essential. Calculate the necessary volume of fluid and select a pump that can deliver that volume at the desired pressure.

Pressure Requirements

Determine the pressure needed for your application. Ensure that the pump selected can meet or exceed this pressure requirement without compromising performance.

Motor Power

The motor power rating influences the pump's efficiency. Opt for a pump with a motor that balances energy consumption and performance.

Material Compatibility

Select pumps made from materials compatible with the fluids being transferred. For corrosive substances, stainless steel, or specialized alloys may be necessary.

Efficiency Ratings

Choose pumps with high-efficiency ratings to minimize energy consumption and operating costs over time.

5. Applications of High Pressure Booster Pumps

High pressure booster pumps find applications across a diverse range of industries. Here are some notable areas:

Water Supply Systems

These pumps are crucial for municipal water supply systems, ensuring adequate pressure levels for distribution.

Agriculture and Irrigation

Farmers utilize booster pumps to elevate water pressure for irrigation systems, ensuring crops receive the necessary hydration.

Fire Fighting Systems

High pressure booster pumps are essential in fire protection systems, providing the necessary water pressure to combat fires effectively.

HVAC Systems

In heating and cooling applications, booster pumps maintain the required pressure for optimal system performance.

Industrial Processes

Various manufacturing processes demand reliable pressure levels, making high pressure booster pumps indispensable.

6. Common Mistakes to Avoid When Selecting a Booster Pump

Selecting the wrong high pressure booster pump can lead to inefficiencies and increased operational costs. Here are common pitfalls to avoid:

Ignoring System Requirements

Failing to evaluate the specific needs of your system can result in selecting a pump that is either over- or under-specified.

Neglecting Maintenance Needs

Some pumps require more maintenance than others. Consider the long-term implications of maintenance when choosing your pump.

Overlooking Installation Space

Ensure the selected pump fits within the designated installation space, accounting for future maintenance access.

Not Consulting Experts

Consulting with industry experts or suppliers can provide valuable insights and help avoid common mistakes.

7. Maintenance Tips for High Pressure Booster Pumps

Regular maintenance is crucial for ensuring the longevity and efficiency of high pressure booster pumps. Here are some essential maintenance tips:

Routine Inspections

Conduct regular inspections to check for leaks, wear, and tear. Early detection of issues can prevent costly repairs.

Monitor Performance

Keep an eye on the pump's performance metrics, including flow rate and pressure, to identify any deviations from normal operations.

Clean Filters and Strainers

Regularly clean and replace filters and strainers to prevent blockages and ensure optimal fluid flow.

Lubricate Moving Parts

Ensure that all moving parts are adequately lubricated to minimize friction and wear.

Follow Manufacturer Guidelines

Adhere to the manufacturer’s maintenance recommendations for optimal performance and longevity.

8. Frequently Asked Questions (FAQs)

1. What is the primary function of a high pressure booster pump?

High pressure booster pumps are designed to increase the pressure of fluids in a system, ensuring efficient flow and operation.

2. How do I determine the right flow rate for my application?

Evaluate your system's requirements by calculating the volume of fluid needed per minute and matching it with pump specifications.

3. What are the signs that my booster pump needs maintenance?

Common signs include unusual noises, reduced flow rate, or leaks around the pump.

4. Can I use a high pressure booster pump for different fluids?

It depends on the materials and design of the pump. Ensure compatibility with the fluid being pumped to avoid damage.

5. What are the benefits of using a multistage pump?

Multistage pumps can deliver higher pressure levels and are ideal for applications requiring significant elevation or pressure boosts.

9. Conclusion

Selecting a quality high pressure booster pump is an essential decision that can significantly affect the efficiency and effectiveness of various industrial applications. By understanding the types of pumps available, key specifications to consider, and common pitfalls to avoid, we can make informed choices that enhance operational performance. Regular maintenance further ensures longevity and reliability, helping industries meet their fluid transfer needs efficiently. Remember to consult with experts and conduct thorough research to select the best pump for your specific requirements.

The 17th China International Powder Metallurgy and Hard Alloy Exhibition

The 2025 17th China International Powder Metallurgy and Hard Alloy Exhibition from March 10-12, 2025, at the Shanghai World Expo Exhibition and Convention Center, Hall H1, B425. We welcome guests to visit.

"Private custom" product design, reliable and durable finished products

"Private custom" like product design, reliable and durable finished products, professional and timely after-sales service. It is the "three basic concepts" that the company adheres to from the beginning until today ".

Experienced market research team, independent product development concept

We have experienced mature market research team, independent product research and development concept, professional design and manufacturing technology so that the company's products can be adjusted according to the specific requirements of customers timely design