Why You Need the Best High Pressure Booster Pump for Optimal Performance

Understanding High Pressure Booster Pumps

High-pressure booster pumps are essential components in various industrial applications where elevated pressure is necessary. These pumps increase the pressure of a fluid, ensuring that it moves efficiently through pipelines, systems, and processes. They play a crucial role in industries such as water treatment, manufacturing, and chemical processing.

The Importance of High Pressure in Industrial Applications

In many industrial settings, maintaining optimal pressure is vital for operational efficiency. High pressure can influence a range of factors, including:

- **Process Efficiency**: Enhanced pressure can lead to faster processing times.

- **Fluid Movement**: High-pressure systems ensure that fluids reach their intended destination swiftly and without interruption.

- **System Reliability**: Proper pressure levels minimize the risk of equipment failure and downtime.

Key Benefits of Using High Pressure Booster Pumps

Investing in the right high-pressure booster pump offers several advantages:

1. Increased Productivity

By maintaining consistent and optimal pressure levels, businesses can achieve higher levels of productivity. This is particularly important in processes such as:

- **Chemical reactions**: Reactions often require specific pressure levels for optimal yield.

- **Hydraulic systems**: Consistent pressure leads to smoother operation and less wear on machinery.

2. Energy Efficiency

Modern high-pressure booster pumps are designed for energy efficiency. They can significantly reduce energy consumption compared to older models, leading to lower operational costs.

3. Extended Equipment Lifespan

Using the best high-pressure booster pump reduces strain on other equipment within the system. This can lead to a longer lifespan for machinery, saving manufacturers money on maintenance and replacement.

4. Enhanced Fluid Quality

Proper pressure levels help maintain the integrity of the fluids being pumped, which is crucial in applications such as pharmaceuticals and food processing. High-quality fluid handling translates into better end products.

Factors to Consider When Choosing a High Pressure Booster Pump

When selecting a high-pressure booster pump, various factors must be examined to ensure optimal performance.

1. Application Requirements

Identify the specific needs of your application. Different processes may require different pressure levels, flow rates, and fluid types.

2. Pump Type

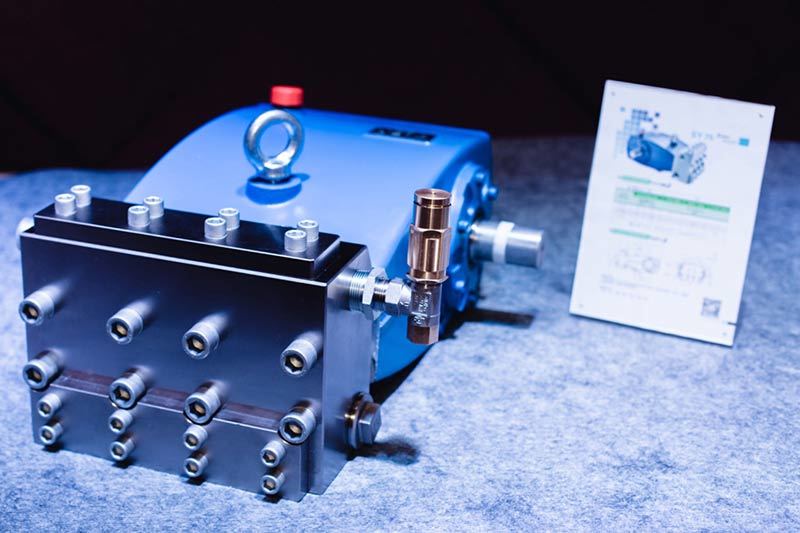

There are several types of high-pressure booster pumps, including:

- **Centrifugal Pumps**: Ideal for applications requiring high flow rates at lower pressures.

- **Positive Displacement Pumps**: Suitable for high-pressure applications with varying flow rates.

Choosing the correct type is crucial for efficiency.

3. Material Selection

The materials used in the construction of the pump must be compatible with the fluids being handled. Common materials include:

- **Stainless Steel**: Highly resistant to corrosion, making it suitable for aggressive fluids.

- **Bronze**: Offers good resistance to seawater and chemical corrosion.

4. Maintenance and Repair

Consider the ease of maintenance and availability of replacement parts. A pump that is easy to service can save time and reduce downtime.

5. Cost vs. Performance

While it might be tempting to select the least expensive option, consider the long-term costs associated with performance and maintenance. Investing in a quality high-pressure booster pump can yield significant savings over time.

Top Features to Look for in a High Pressure Booster Pump

When searching for the best high-pressure booster pump, certain features can enhance performance and reliability.

1. Variable Speed Drives

Pumps with variable speed drives allow for adjustable flow rates. This flexibility results in optimized energy usage and improved process control.

2. Integrated Controls

Advanced pumps come with built-in control systems, enabling automated operation and monitoring. This technology can enhance precision and reduce the risk of human error.

3. High Efficiency Ratings

Look for pumps that have high-efficiency ratings. These models consume less energy and reduce operational costs.

4. Noise Reduction Technology

Noise can be a significant issue in industrial settings. Selecting a pump designed with noise reduction features can improve workplace comfort.

5. Safety Features

Safety is paramount in any industrial application. Ensure that the pump has built-in safety features, such as pressure relief valves and protective shut-off systems.

Case Studies: Successful Implementation of High Pressure Booster Pumps

Real-world examples of high-pressure booster pump applications can highlight their importance.

1. Water Treatment Facilities

Many water treatment facilities have implemented high-pressure booster pumps to enhance filtration and treatment processes. These pumps ensure consistent pressure, leading to more efficient water purification.

2. Manufacturing Plants

In manufacturing, high-pressure pumps are used in hydraulic systems to operate machinery. A notable case involved a manufacturing plant that upgraded to a variable-speed high-pressure booster pump, resulting in a 15% increase in productivity.

FAQs about High Pressure Booster Pumps

1. What is a high-pressure booster pump?

A high-pressure booster pump is a device designed to increase the pressure of fluids in various industrial applications.

2. How do I know which booster pump is right for my application?

Consider factors such as flow rate, pressure requirements, fluid type, and maintenance needs when selecting a pump.

3. What are the signs that my booster pump needs maintenance?

Common signs include unusual noises, fluctuating pressure, and leaks around the pump.

4. Can high-pressure booster pumps be used for both water and chemicals?

Yes, but it's essential to choose a pump made from materials compatible with the specific fluids.

5. How often should I service my high-pressure booster pump?

Regular maintenance should be performed at least annually, but more frequent checks may be warranted depending on usage and operating conditions.

Conclusion

Selecting the best high-pressure booster pump is a crucial decision that impacts operational efficiency, productivity, and overall performance in industrial applications. By understanding the importance of high pressure, considering essential features, and evaluating specific application requirements, businesses can make informed choices. Investing in a high-quality high-pressure booster pump not only enhances performance but also ensures long-term reliability and cost savings. As industries continue to evolve, having the right pumping solutions in place will be key to maintaining a competitive edge.

The 17th China International Powder Metallurgy and Hard Alloy Exhibition

The 2025 17th China International Powder Metallurgy and Hard Alloy Exhibition from March 10-12, 2025, at the Shanghai World Expo Exhibition and Convention Center, Hall H1, B425. We welcome guests to visit.

"Private custom" product design, reliable and durable finished products

"Private custom" like product design, reliable and durable finished products, professional and timely after-sales service. It is the "three basic concepts" that the company adheres to from the beginning until today ".

Experienced market research team, independent product development concept

We have experienced mature market research team, independent product research and development concept, professional design and manufacturing technology so that the company's products can be adjusted according to the specific requirements of customers timely design