Unlocking Efficiency: The Advantages of Classy High Pressure Plunger Pumps

Table of Contents

1. Introduction to High Pressure Plunger Pumps

2. Understanding the Mechanics of Plunger Pumps

3. Key Advantages of High Pressure Plunger Pumps

3.1 Enhanced Efficiency and Performance

3.2 Versatility Across Applications

3.3 Reduced Maintenance Costs

4. Comparing High Pressure Plunger Pumps to Other Pump Types

5. Applications of High Pressure Plunger Pumps in Various Industries

5.1 Oil and Gas

5.2 Chemical Processing

5.3 Water Treatment

6. Choosing the Right Plunger Pump for Your Needs

7. Maintenance Best Practices for Longevity

8. Frequently Asked Questions (FAQs)

9. Conclusion

1. Introduction to High Pressure Plunger Pumps

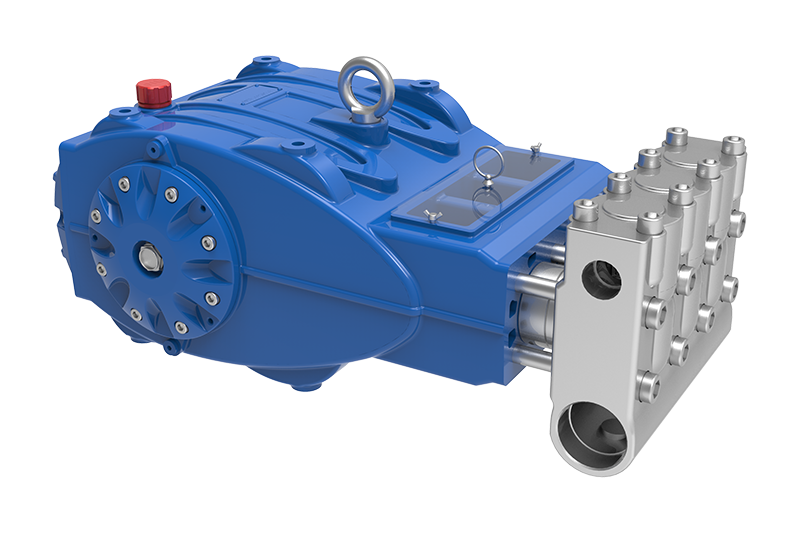

High pressure plunger pumps are essential tools in the industrial sector, designed to handle the demanding requirements of various applications. Their unique design and functionality enable them to deliver high pressure and precise flow rates, making them ideal for numerous industries. This article aims to explore the myriad advantages these pumps offer, from enhanced efficiency to reduced maintenance costs, providing insights into why they are increasingly favored in modern industrial settings.

2. Understanding the Mechanics of Plunger Pumps

At the core of high pressure plunger pumps lies a simple yet effective mechanism. The pump consists of one or more plungers that move back and forth within a cylinder, creating a vacuum that draws fluid in and then expelling it at high pressure. This action allows for precise control over fluid flow and pressure, making plunger pumps suitable for handling a wide range of fluids, including viscous and abrasive materials.

3. Key Advantages of High Pressure Plunger Pumps

3.1 Enhanced Efficiency and Performance

One of the standout features of high pressure plunger pumps is their ability to operate with high efficiency. They are capable of achieving higher pressures than many other types of pumps, which translates into improved performance in various applications. The precision engineering involved in their design ensures minimal energy loss during operation, allowing for significant cost savings in energy consumption.

3.2 Versatility Across Applications

High pressure plunger pumps are remarkably versatile, making them suitable for a wide array of applications. Whether in oil and gas extraction, chemical processing, or water treatment, these pumps can be adapted to meet specific industry requirements. Their ability to handle different types of fluids, including corrosive and abrasive materials, further enhances their usability across various sectors.

3.3 Reduced Maintenance Costs

Investing in high pressure plunger pumps can lead to lower overall maintenance costs. The robust construction of these pumps reduces wear and tear, resulting in longer operational lifespans. Additionally, their design minimizes the likelihood of leaks and other common pump failures, reducing downtime and maintenance expenses.

4. Comparing High Pressure Plunger Pumps to Other Pump Types

When evaluating pumping solutions, it's essential to compare high pressure plunger pumps with other pump types, such as centrifugal pumps and diaphragm pumps. High pressure plunger pumps typically excel in applications requiring high pressure and precise flow control, while centrifugal pumps are more suited for low-pressure applications. Understanding these differences can help industries select the most effective pumping solution for their specific needs.

5. Applications of High Pressure Plunger Pumps in Various Industries

5.1 Oil and Gas

In the oil and gas industry, high pressure plunger pumps are vital for processes such as hydraulic fracturing and well stimulation. Their ability to deliver high-pressure fluids accurately is crucial for maximizing extraction efficiency and ensuring safety in operations.

5.2 Chemical Processing

High pressure plunger pumps are extensively used in chemical processing to handle corrosive fluids and ensure precise dosing. Their robust design allows them to manage aggressive chemicals without compromising performance, making them a reliable choice for chemical manufacturers.

5.3 Water Treatment

In water treatment facilities, these pumps play a significant role in transporting water under high pressure for filtration and purification processes. Their efficiency contributes to the overall effectiveness of water treatment operations, ensuring the delivery of clean and safe drinking water.

6. Choosing the Right Plunger Pump for Your Needs

Selecting the appropriate high pressure plunger pump involves understanding your specific application requirements. Factors such as fluid viscosity, temperature, and pressure ratings should be considered. Collaborating with a knowledgeable supplier can help identify the best pump for your operational needs.

7. Maintenance Best Practices for Longevity

To ensure the longevity and optimal performance of high pressure plunger pumps, regular maintenance is essential. Key practices include routine inspections, timely replacement of worn components, and ensuring proper lubrication. Implementing a structured maintenance schedule can significantly reduce the risk of unexpected failures and enhance the lifespan of the equipment.

8. Frequently Asked Questions (FAQs)

What is a high pressure plunger pump?

A high pressure plunger pump is a type of positive displacement pump that uses one or more plungers to create high pressure and precise flow control for various fluids.

What industries commonly use high pressure plunger pumps?

High pressure plunger pumps are utilized in several industries, including oil and gas, chemical processing, and water treatment, among others.

How do high pressure plunger pumps compare to centrifugal pumps?

High pressure plunger pumps are more effective in applications requiring high pressure and precise flow control, while centrifugal pumps are more suitable for low-pressure applications.

What maintenance is required for high pressure plunger pumps?

Regular inspections, timely replacement of worn components, and proper lubrication are key maintenance practices for ensuring the longevity of high pressure plunger pumps.

Can high pressure plunger pumps handle corrosive materials?

Yes, high pressure plunger pumps are designed to handle aggressive chemicals and corrosive fluids, making them suitable for various industrial applications.

9. Conclusion

High pressure plunger pumps represent a powerful solution for industries seeking efficiency and reliability in fluid management. Their enhanced performance, versatility, and cost-effectiveness make them an ideal choice for a wide range of applications. By understanding their advantages and implementing proper maintenance practices, industries can unlock the full potential of these pumps, ensuring smooth operations and contributing to overall productivity. As industries continue to evolve, high pressure plunger pumps will remain at the forefront of technology, driving efficiency and effectiveness in fluid handling processes.

The 17th China International Powder Metallurgy and Hard Alloy Exhibition

The 2025 17th China International Powder Metallurgy and Hard Alloy Exhibition from March 10-12, 2025, at the Shanghai World Expo Exhibition and Convention Center, Hall H1, B425. We welcome guests to visit.

"Private custom" product design, reliable and durable finished products

"Private custom" like product design, reliable and durable finished products, professional and timely after-sales service. It is the "three basic concepts" that the company adheres to from the beginning until today ".

Experienced market research team, independent product development concept

We have experienced mature market research team, independent product research and development concept, professional design and manufacturing technology so that the company's products can be adjusted according to the specific requirements of customers timely design