Why Choose Advanced Industrial High Pressure Pumps for Your Operations?

Table of Contents

- 1. Introduction to Advanced Industrial High Pressure Pumps

- 2. Understanding High Pressure Pumps: The Basics

- 3. Advantages of High Pressure Pumps in Industrial Applications

- 4. The Technology Behind Advanced High Pressure Pumps

- 5. Diverse Applications of High Pressure Pumps Across Industries

- 6. Choosing the Right High Pressure Pump for Your Needs

- 7. Maintenance Tips for Longevity and Efficiency

- 8. Future Trends in High Pressure Pump Technology

- 9. Conclusion

- 10. Frequently Asked Questions (FAQs)

1. Introduction to Advanced Industrial High Pressure Pumps

In today's fast-paced industrial landscape, **efficiency** and **reliability** are paramount. Advanced industrial high pressure pumps play a pivotal role in achieving these goals. These pumps are engineered to handle demanding applications, making them essential equipment in various sectors, from manufacturing to oil and gas. In this article, we will delve into the compelling reasons to choose high pressure pumps for your operations, highlighting their benefits, applications, and the technology that drives them.

2. Understanding High Pressure Pumps: The Basics

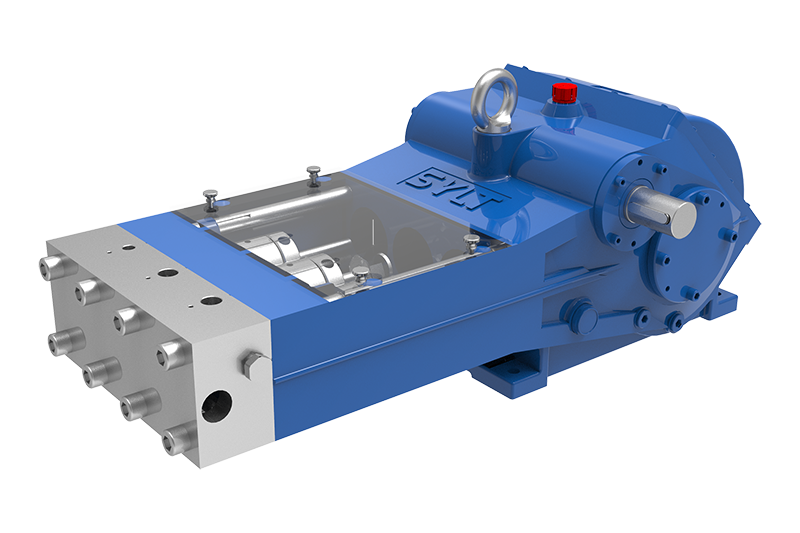

High pressure pumps are specialized devices designed to generate high pressure liquids and gases in a controlled manner. They operate on the principle of converting mechanical energy into hydraulic energy, enabling the transport of fluids at elevated pressures. Common types of high pressure pumps include:

2.1 Types of High Pressure Pumps

- **Positive Displacement Pumps**: These pumps operate by trapping a fixed volume of fluid and forcing it through the discharge pipe, making them ideal for high viscosity fluids.

- **Centrifugal Pumps**: These utilize a rotating impeller to impart velocity to the fluid, best suited for low viscosity fluids at high flow rates.

Understanding these basic types is crucial in selecting the right pump for specific applications.

3. Advantages of High Pressure Pumps in Industrial Applications

The adoption of advanced high pressure pumps in industrial settings offers numerous advantages:

3.1 Enhanced Performance and Efficiency

High pressure pumps excel at delivering consistent pressure levels, resulting in improved performance across various processes. They can efficiently transport fluids over long distances, reducing energy consumption and operational costs.

3.2 Increased Reliability

With robust construction and advanced materials, high pressure pumps are designed to withstand harsh environments and demanding conditions. This reliability minimizes the risk of breakdowns and unplanned maintenance, ultimately boosting productivity.

3.3 Versatility in Applications

High pressure pumps can be utilized in diverse applications, from chemical processing to food and beverage manufacturing. Their versatility enables businesses to adapt to changing operational requirements.

4. The Technology Behind Advanced High Pressure Pumps

Modern high pressure pumps integrate cutting-edge technology to enhance performance and efficiency. Key innovations include:

4.1 Automation and Smart Technology

Many advanced high pressure pumps now feature smart technology that allows for real-time monitoring and automation. This technology helps optimize performance, predict maintenance needs, and reduce human error.

4.2 Energy Efficiency Innovations

Energy-efficient designs, such as variable frequency drives (VFDs), enable pumps to adjust their speed according to demand, reducing energy consumption and operational costs.

5. Diverse Applications of High Pressure Pumps Across Industries

The versatility of high pressure pumps allows them to serve various industries effectively:

5.1 Oil and Gas Sector

In the oil and gas industry, high pressure pumps are crucial for drilling, production, and refining processes. They transport fluids under high pressure, ensuring efficient operations.

5.2 Water Treatment Facilities

High pressure pumps play a vital role in water treatment and desalination plants, helping to move water through filtration systems and reverse osmosis processes.

5.3 Manufacturing and Chemical Processing

In manufacturing and chemical processing, these pumps are used for coolant circulation, component cleaning, and the transportation of chemicals, ensuring operational efficiency and safety.

6. Choosing the Right High Pressure Pump for Your Needs

Selecting the right high pressure pump requires an understanding of your specific operational needs:

6.1 Assessing Flow Rate and Pressure Requirements

Evaluate the required flow rate and pressure for your application. This information is crucial in determining the appropriate pump size and type.

6.2 Material Compatibility

Consider the compatibility of the pump materials with the fluids you will be handling. Corrosion-resistant materials are essential for transporting aggressive chemicals.

6.3 Manufacturer Reputation

Choose a manufacturer known for engineering quality pumps with a proven track record in your industry. Research customer reviews and case studies to gauge their reliability.

7. Maintenance Tips for Longevity and Efficiency

Regular maintenance is essential to ensure the longevity and efficiency of high pressure pumps:

7.1 Routine Inspections

Conduct routine inspections to identify wear and tear. Check seals, gaskets, and bearings for signs of damage or degradation.

7.2 Regular Cleaning

Keep the pump clean from debris and contaminants that can hinder performance. Regular cleaning helps maintain efficiency and extends the pump's lifespan.

7.3 Scheduled Servicing

Establish a scheduled maintenance routine with qualified technicians to perform necessary servicing and repairs. This proactive approach minimizes downtime and operational disruptions.

8. Future Trends in High Pressure Pump Technology

As technology evolves, we can expect exciting developments in high pressure pump systems:

8.1 Integration of IoT

The integration of Internet of Things (IoT) technology will enable high pressure pumps to connect to centralized monitoring systems, allowing for predictive maintenance and real-time data analysis.

8.2 Sustainable Solutions

The push for sustainability will drive innovations in energy-efficient designs and materials that reduce environmental impact while maintaining high performance.

9. Conclusion

Advanced industrial high pressure pumps stand as a cornerstone in enhancing operational efficiency across various industries. Their ability to deliver reliable performance, coupled with modern technological innovations, makes them indispensable assets for businesses aiming to optimize their processes. By understanding their advantages, applications, and the considerations for selection and maintenance, companies can leverage these pumps to achieve greater productivity and operational success.

10. Frequently Asked Questions (FAQs)

10.1 What industries benefit the most from high pressure pumps?

High pressure pumps are beneficial in industries such as oil and gas, water treatment, manufacturing, and chemical processing.

10.2 How do I determine the right size of high pressure pump for my application?

Assess your specific flow rate and pressure requirements, and consult with manufacturers to find the optimal pump size for your needs.

10.3 What maintenance practices are crucial for high pressure pumps?

Routine inspections, regular cleaning, and scheduled servicing by qualified technicians are essential for maintaining high pressure pumps.

10.4 Can high pressure pumps handle corrosive fluids?

Yes, many high pressure pumps are designed with corrosion-resistant materials to handle aggressive fluids safely and efficiently.

10.5 What are the latest trends in high pressure pump technology?

Current trends include the integration of IoT for predictive maintenance and a focus on sustainable, energy-efficient designs.

The 17th China International Powder Metallurgy and Hard Alloy Exhibition

The 2025 17th China International Powder Metallurgy and Hard Alloy Exhibition from March 10-12, 2025, at the Shanghai World Expo Exhibition and Convention Center, Hall H1, B425. We welcome guests to visit.

"Private custom" product design, reliable and durable finished products

"Private custom" like product design, reliable and durable finished products, professional and timely after-sales service. It is the "three basic concepts" that the company adheres to from the beginning until today ".

Experienced market research team, independent product development concept

We have experienced mature market research team, independent product research and development concept, professional design and manufacturing technology so that the company's products can be adjusted according to the specific requirements of customers timely design