Unlocking Efficiency: The Benefits of Advanced High Pressure Water Jet Pumps

Table of Contents

1. Introduction to High Pressure Water Jet Pumps

2. Understanding the Technology Behind High Pressure Water Jet Pumps

- 2.1 How High Pressure Water Jet Pumps Work

- 2.2 Types of High Pressure Water Jet Pumps

3. Key Benefits of Advanced High Pressure Water Jet Pumps

- 3.1 Increased Efficiency

- 3.2 Eco-Friendliness and Sustainability

- 3.3 Versatility in Applications

4. Applications of High Pressure Water Jet Pumps in Industry

5. Maintenance Tips for Optimal Performance

6. Frequently Asked Questions

7. Conclusion

1. Introduction to High Pressure Water Jet Pumps

In today's competitive industrial landscape, efficiency and productivity are paramount. Businesses continuously seek innovative solutions to streamline operations and reduce costs. One such solution is the advanced high-pressure water jet pump. These machines have transformed various sectors, offering a powerful, efficient, and environmentally-friendly method for tasks ranging from cleaning and cutting to surface preparation. In this article, we will delve into the benefits, technology, applications, and maintenance of high-pressure water jet pumps, providing a comprehensive understanding of why they are vital for modern industries.

2. Understanding the Technology Behind High Pressure Water Jet Pumps

High-pressure water jet pumps utilize the power of water at extremely high pressures to perform a variety of tasks effectively. The technology is not only fascinating but also showcases significant advancements in engineering and design.

2.1 How High Pressure Water Jet Pumps Work

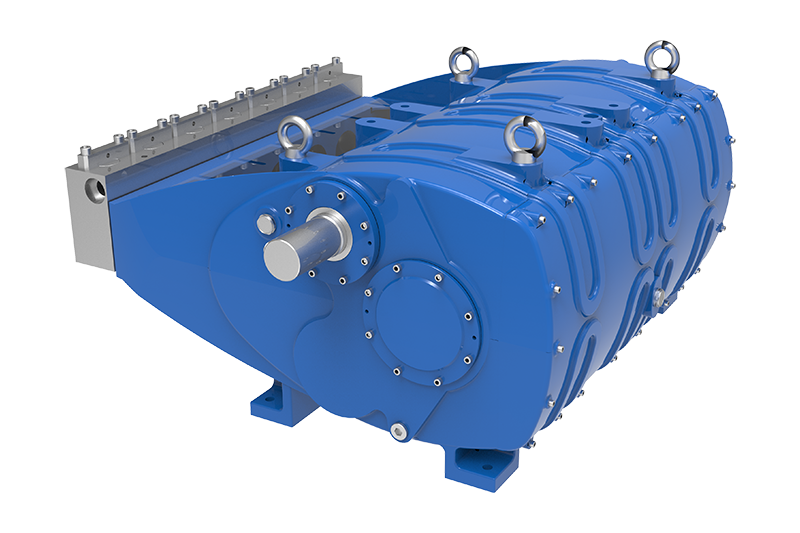

The operation of a high-pressure water jet pump begins with a motor that drives a pump, pressurizing the water to levels that can exceed 60,000 psi (pounds per square inch). This pressurized water is then expelled through a specially designed nozzle, creating a high-velocity jet stream. The kinetic energy generated by this stream can cut, clean, or abrade surfaces with remarkable precision.

The efficiency of this process lies in the ability to adjust pressure and flow rates, allowing operators to tailor the system to specific tasks. When combined with advanced nozzles and accessories, high-pressure water jet pumps can achieve exceptional results in various applications.

2.2 Types of High Pressure Water Jet Pumps

There are several types of high-pressure water jet pumps available on the market, each designed for specific applications and industries:

- **Diaphragm Pumps**: Ideal for lower flow rates, these pumps utilize a diaphragm to create pressure. They are suitable for smaller-scale operations.

- **Plunger Pumps**: Known for their durability and high-efficiency levels, plunger pumps are commonly used in industrial applications requiring high flow and pressure.

- **Electric vs. Diesel Pumps**: Electric pumps are typically quieter and more energy-efficient for indoor use, while diesel pumps offer portability and power for outdoor environments.

Understanding these types helps industries choose the appropriate pump for their specific needs.

3. Key Benefits of Advanced High Pressure Water Jet Pumps

The advantages of using advanced high-pressure water jet pumps extend beyond just functionality.

3.1 Increased Efficiency

High-pressure water jet pumps are designed for maximum efficiency. They can complete tasks in a fraction of the time required by traditional methods. For instance, using these pumps for surface cleaning can significantly reduce labor costs and downtime, allowing companies to complete jobs more swiftly and move on to the next project.

3.2 Eco-Friendliness and Sustainability

One of the most significant benefits of high-pressure water jet pumps is their eco-friendliness. They minimize the need for harsh chemicals, reducing environmental impact. The use of high-pressure water jets can effectively remove contaminants, grease, and other materials without resorting to toxic substances, making them a sustainable choice for industries focused on environmental responsibility.

3.3 Versatility in Applications

High-pressure water jet pumps are incredibly versatile and can be used in a wide range of applications, including:

- **Industrial Cleaning**: They are effective in cleaning machinery, equipment, and surfaces.

- **Concrete Cutting and Removal**: High-pressure jets can cut through concrete, making them essential in construction and demolition.

- **Surface Preparation**: Water jet pumps are ideal for preparing surfaces for painting or coating, ensuring optimal adhesion and finish.

This versatility makes them an indispensable tool in many industries.

4. Applications of High Pressure Water Jet Pumps in Industry

High-pressure water jet pumps find extensive applications across various sectors.

- **Manufacturing and Production**: They are used for cleaning and maintaining machinery, ensuring optimal performance and extending equipment life.

- **Construction and Demolition**: High-pressure water jets efficiently remove materials and cut through concrete, making them valuable in construction projects.

- **Maritime Industry**: These pumps are employed for hull cleaning and maintenance of ships, preventing biofouling and enhancing performance.

- **Food Industry**: They are used for cleaning food processing equipment, ensuring hygiene and compliance with health regulations.

Understanding these applications allows businesses to leverage high-pressure water jet pumps to enhance operations and satisfy industry standards.

5. Maintenance Tips for Optimal Performance

To ensure the longevity and effectiveness of high-pressure water jet pumps, regular maintenance is essential. Here are some tips:

- **Regular Inspections**: Conduct routine checks for wear and tear on components, including hoses and nozzles.

- **Keep It Clean**: After use, clean the pump and remove any debris to prevent clogging and damage.

- **Check Fluid Levels**: Ensure that hydraulic oils and other fluids are at the correct levels for optimal performance.

- **Follow Manufacturer Guidelines**: Adhere to the specific maintenance schedule and practices recommended by the manufacturer.

These practices will help maintain peak performance and extend the life of high-pressure water jet pumps.

6. Frequently Asked Questions

What is the typical pressure range for high-pressure water jet pumps?

High-pressure water jet pumps can operate anywhere from 10,000 psi to over 60,000 psi, depending on the application and specific needs.

Are high-pressure water jet pumps environmentally friendly?

Yes, they are environmentally friendly as they require minimal or no chemicals for operations, significantly reducing environmental impact.

What industries benefit most from using high-pressure water jet pumps?

Industries such as manufacturing, construction, maritime, and food processing benefit greatly from high-pressure water jet pumps due to their efficiency and versatility.

How do I choose the right high-pressure water jet pump for my needs?

Consider factors such as flow rate, pressure requirements, and specific applications when selecting a high-pressure water jet pump. Consulting with suppliers can also provide valuable insights.

What maintenance is required for high-pressure water jet pumps?

Regular inspections, cleaning, checking fluid levels, and following manufacturer guidelines are essential for maintaining high-pressure water jet pumps.

7. Conclusion

In conclusion, advanced high-pressure water jet pumps represent a pivotal innovation in industrial efficiency and productivity. Their ability to perform a variety of tasks with unmatched speed and effectiveness, coupled with their eco-friendly nature, makes them an invaluable asset for modern industries. By understanding the technology behind these pumps, their numerous benefits, and best practices for maintenance, businesses can unlock their full potential. Investing in high-pressure water jet pumps not only enhances operational efficiency but also supports sustainability, paving the way for a greener future in industrial practices.

The 17th China International Powder Metallurgy and Hard Alloy Exhibition

The 2025 17th China International Powder Metallurgy and Hard Alloy Exhibition from March 10-12, 2025, at the Shanghai World Expo Exhibition and Convention Center, Hall H1, B425. We welcome guests to visit.

"Private custom" product design, reliable and durable finished products

"Private custom" like product design, reliable and durable finished products, professional and timely after-sales service. It is the "three basic concepts" that the company adheres to from the beginning until today ".

Experienced market research team, independent product development concept

We have experienced mature market research team, independent product research and development concept, professional design and manufacturing technology so that the company's products can be adjusted according to the specific requirements of customers timely design