Unlocking Efficiency: The Advantages of Discount High Pressure Low Flow Pumps for Industrial Applications

Table of Contents

- 1. Introduction to High Pressure Low Flow Pumps

- 2. Understanding the Benefits of Discount High Pressure Low Flow Pumps

- 2.1 Cost-Effectiveness of Discount Pumps

- 2.2 Energy Efficiency and Sustainability

- 2.3 Space-Saving Design

- 3. Applications of High Pressure Low Flow Pumps in Industries

- 4. Key Features of High Pressure Low Flow Pumps

- 5. Choosing the Right High Pressure Low Flow Pump

- 6. Frequently Asked Questions

- 7. Conclusion

1. Introduction to High Pressure Low Flow Pumps

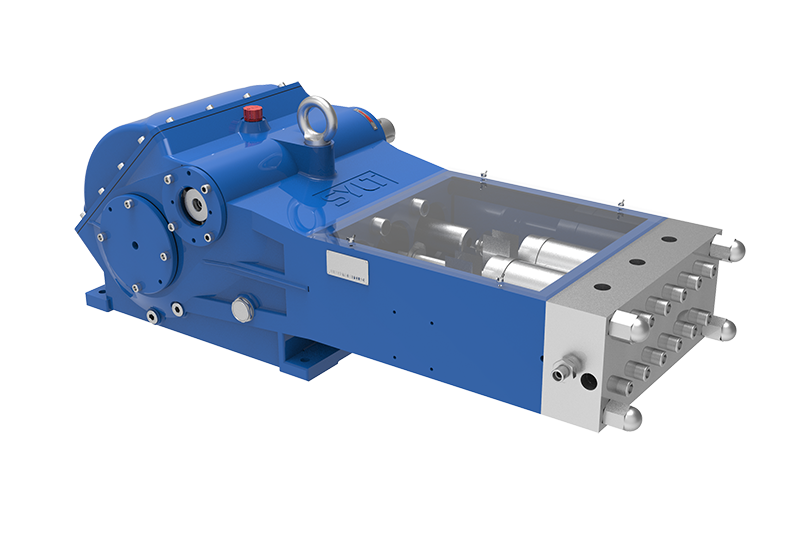

High pressure low flow pumps are specialized devices designed to operate efficiently in conditions requiring high pressure but low fluid displacement. These pumps are crucial in various industrial applications where precise fluid control is essential. As industries strive for enhanced efficiency and reduced operational costs, discount high pressure low flow pumps present a compelling solution, offering both performance and affordability.

2. Understanding the Benefits of Discount High Pressure Low Flow Pumps

2.1 Cost-Effectiveness of Discount Pumps

One of the most significant advantages of discount high pressure low flow pumps is their **cost-effectiveness**. These pumps provide substantial savings compared to their full-priced counterparts without compromising quality. Businesses can capitalize on lower initial investments, allowing them to allocate resources to other critical areas while still obtaining reliable performance.

2.2 Energy Efficiency and Sustainability

In today's environmentally conscious world, energy efficiency is paramount. Discount high pressure low flow pumps are designed to operate with minimal energy consumption, significantly reducing utility bills. Moreover, their efficiency contributes to sustainability efforts by minimizing waste and lowering carbon footprints. This aspect is particularly appealing to industries aiming to meet environmental regulations and enhance their sustainability profiles.

2.3 Space-Saving Design

Many industrial facilities face limitations in space. Discount high pressure low flow pumps are often compact in design, making them ideal for installations in tight spaces. This space-saving feature allows businesses to optimize their layouts while ensuring that all necessary equipment is functional and accessible.

3. Applications of High Pressure Low Flow Pumps in Industries

High pressure low flow pumps find utility across various sectors, each benefitting from their unique capabilities.

3.1 Chemical Processing

In chemical processing, precision is vital. These pumps handle aggressive liquids and chemicals efficiently, ensuring that processes such as mixing and transferring occur seamlessly. Their ability to maintain high pressure at low flow rates makes them ideal for applications that require careful control of chemical reactions.

3.2 Water Treatment

Water treatment plants utilize high pressure low flow pumps for tasks such as filtration and disinfection. These pumps ensure that water is treated effectively, meeting safety standards and improving overall water quality. Their efficiency helps minimize operating costs while guaranteeing reliable performance.

3.3 Food and Beverage Industry

The food and beverage industry demands stringent hygiene standards. **High pressure low flow pumps** are equipped with features that facilitate easy cleaning and maintenance, making them suitable for transferring liquids such as syrups, juices, and sauces. Their ability to operate under high pressure also ensures that products are delivered consistently and safely.

4. Key Features of High Pressure Low Flow Pumps

Understanding the essential features of high pressure low flow pumps can help businesses select the most suitable option for their needs.

4.1 Durability and Reliability

Quality engineering ensures that discount high pressure low flow pumps are built to last. Constructed with durable materials, these pumps can withstand harsh conditions, making them reliable for continuous operation. Businesses can rest assured that they are investing in equipment that will serve them well over time.

4.2 Low Maintenance Requirements

Maintenance is a crucial factor in any industrial operation. Discount high pressure low flow pumps require minimal maintenance, which translates to lower operational costs and reduced downtime. Their design often incorporates features that simplify maintenance tasks, allowing for swift servicing when needed.

5. Choosing the Right High Pressure Low Flow Pump

When selecting a high pressure low flow pump, several factors should be considered:

1. **Flow Rate Requirements**: Determine the necessary flow rate for your specific application.

2. **Pressure Specifications**: Assess the required pressure to ensure that the pump meets operational needs.

3. **Fluid Characteristics**: Identify the nature of the fluid being pumped, including viscosity and corrosiveness, to choose a compatible pump material.

4. **Installation Space**: Consider the available space and select a pump that fits comfortably within your operational setup.

5. **Budget**: Evaluate the cost versus performance to find a balance that fits your financial constraints.

6. Frequently Asked Questions

What are high pressure low flow pumps used for?

High pressure low flow pumps are used in various industries for applications requiring high pressure and low flow rates, such as chemical processing, water treatment, and food and beverage production.

How do discount pumps compare to regular models?

Discount pumps offer similar performance and reliability as regular models but at a lower price point, making them cost-effective solutions for businesses seeking efficiency without overspending.

Are high pressure low flow pumps energy-efficient?

Yes, these pumps are designed for energy efficiency, which helps reduce operational costs while contributing to sustainability efforts.

What materials are typically used in high pressure low flow pumps?

Common materials include stainless steel, plastic, and other corrosion-resistant materials, ensuring durability and compatibility with various fluids.

How can I maintain my high pressure low flow pump?

Regularly inspect the pump, check for leaks, and follow the manufacturer’s guidelines for servicing and maintenance to ensure optimal performance.

7. Conclusion

In conclusion, discount high pressure low flow pumps present a remarkable opportunity for industries seeking to enhance efficiency, reduce costs, and improve operational performance. By understanding their benefits, applications, and features, businesses can make informed decisions that align with their operational needs and financial goals. Investing in these pumps not only optimizes performance but also supports a sustainable future in industrial operations. Embrace the power of discount high pressure low flow pumps and unlock new levels of efficiency in your operations.

The 17th China International Powder Metallurgy and Hard Alloy Exhibition

The 2025 17th China International Powder Metallurgy and Hard Alloy Exhibition from March 10-12, 2025, at the Shanghai World Expo Exhibition and Convention Center, Hall H1, B425. We welcome guests to visit.

"Private custom" product design, reliable and durable finished products

"Private custom" like product design, reliable and durable finished products, professional and timely after-sales service. It is the "three basic concepts" that the company adheres to from the beginning until today ".

Experienced market research team, independent product development concept

We have experienced mature market research team, independent product research and development concept, professional design and manufacturing technology so that the company's products can be adjusted according to the specific requirements of customers timely design