Enhancing Efficiency: Why You Need a Quality High Pressure Booster Pump

Table of Contents

- 1. Introduction to High Pressure Booster Pumps

- 2. Understanding High Pressure Booster Pumps

- 3. The Importance of Efficiency in Industrial Operations

- 4. Benefits of Investing in Quality High Pressure Booster Pumps

- 4.1 Cost Savings and Energy Efficiency

- 4.2 Enhanced System Performance

- 4.3 Reliability and Durability

- 5. Choosing the Right High Pressure Booster Pump

- 6. Installation and Maintenance of High Pressure Booster Pumps

- 7. FAQs about High Pressure Booster Pumps

- 8. Conclusion

1. Introduction to High Pressure Booster Pumps

In the realm of industrial operations, efficiency is paramount. Among various components that contribute to operational efficiency, **high pressure booster pumps** stand out as essential machinery. These pumps are designed not just to elevate pressure but to optimize performance and reliability across various applications, including water supply, oil and gas, and chemical processing.

In this article, we delve into the significance of high pressure booster pumps, the essential features to look for, and why investing in quality is crucial for ensuring optimal performance and longevity.

2. Understanding High Pressure Booster Pumps

High pressure booster pumps serve to increase the pressure of a fluid within a system, aiding in the efficient transportation and distribution of that fluid. To fully appreciate the role of these pumps, it's important to understand their working principles and the different types available.

2.1 Working Principle of High Pressure Booster Pumps

High pressure booster pumps operate based on the principle of converting mechanical energy into hydraulic energy. They utilize a motor to drive an impeller, which creates a pressure differential that draws fluid into the pump and pushes it out at a higher pressure.

The design of the impeller and the pump casing are crucial in determining the pump's efficiency and flow characteristics. The better the design, the less energy is wasted, leading to reduced operational costs and increased efficiency.

2.2 Types of High Pressure Booster Pumps

There are several types of high pressure booster pumps, each with unique applications:

- **Centrifugal Pumps**: Best suited for applications requiring high flow rates at moderate pressures.

- **Positive Displacement Pumps**: Ideal for scenarios needing precise flow rates and high pressure, these pumps work by trapping a fixed amount of fluid and forcing it into the discharge pipe.

- **Multistage Pumps**: Designed to generate high pressures, these pumps consist of multiple impellers and are frequently used in applications such as reverse osmosis and water treatment.

Understanding these types helps in selecting the right pump for specific applications.

3. The Importance of Efficiency in Industrial Operations

Efficiency in industrial operations can lead to significant cost savings, improved product quality, and enhanced competitiveness. In particular, the efficiency of fluid transportation systems is vital, as inefficiencies can result in wasted resources, increased downtime, and higher operational costs.

High pressure booster pumps play a pivotal role in optimizing these systems. By elevating fluid pressure, they minimize energy consumption while maximizing output. This alignment of pressure and flow rates directly translates into operational efficiency.

4. Benefits of Investing in Quality High Pressure Booster Pumps

The quality of a high pressure booster pump significantly influences its performance and longevity. Here are the key benefits of investing in high-quality pumps:

4.1 Cost Savings and Energy Efficiency

A quality high pressure booster pump operates more efficiently, reducing energy consumption and resulting in lower utility bills. Over time, these savings can outweigh the initial purchase price. Moreover, high-quality pumps tend to require less maintenance, further reducing operational costs.

4.2 Enhanced System Performance

Quality pumps offer consistent performance, translating to better system reliability and efficiency. They maintain optimal flow rates and pressures, improving the overall productivity of industrial processes and reducing the risk of downtimes caused by equipment failures.

4.3 Reliability and Durability

Investing in a quality high pressure booster pump ensures that the equipment is built to withstand rigorous operating conditions. Durable materials and superior construction methods contribute to longer life spans and fewer breakdowns, ultimately enhancing operational reliability.

5. Choosing the Right High Pressure Booster Pump

Selecting the appropriate high pressure booster pump involves several considerations, including application requirements, fluid characteristics, and potential operational challenges.

5.1 Key Features to Consider

When considering a high pressure booster pump for your needs, focus on the following features:

- **Pressure Rating**: Ensure the pump can handle the required pressure levels for your application.

- **Flow Capacity**: Consider the volume of fluid that needs to be moved and select a pump that meets or exceeds that requirement.

- **Material Compatibility**: The materials used in the pump should be compatible with the fluid being transported to prevent corrosion or degradation.

- **Energy Efficiency**: Look for pumps with high efficiency ratings to minimize energy consumption.

5.2 Common Mistakes to Avoid When Selecting a Pump

Avoiding common pitfalls can save time and resources:

- **Underestimating Pressure Needs**: Always account for potential pressure drops in the system, ensuring the pump can handle maximum required pressures.

- **Neglecting Maintenance Requirements**: Opt for pumps that are easy to maintain and have available support, as this impacts long-term performance.

- **Ignoring Manufacturer Reputation**: Choose pumps from reputable manufacturers known for quality and reliability.

6. Installation and Maintenance of High Pressure Booster Pumps

Proper installation and maintenance of high pressure booster pumps is essential for optimal performance and longevity.

Follow these essential guidelines:

- **Installation**: Engage qualified personnel with expertise in pump installation to ensure proper setup. Pay careful attention to alignment, mounting, and piping connections to prevent leaks and ensure efficiency.

- **Regular Maintenance**: Implement a routine maintenance schedule that includes inspections, filter cleaning, and lubrication where necessary. Adhering to the maintenance guidelines provided by the manufacturer can reduce breakdowns and enhance performance.

7. FAQs about High Pressure Booster Pumps

**Q1: What applications are high pressure booster pumps used for?**

A1: High pressure booster pumps are commonly employed in industries such as water supply, oil and gas, chemical processing, and agriculture, where high flow rates and pressures are essential.

**Q2: How do I know if my system needs a booster pump?**

A2: If you experience low water pressure or insufficient flow rates in your systems, a booster pump may be necessary to enhance performance.

**Q3: Can high pressure booster pumps handle corrosive fluids?**

A3: Yes, but it’s crucial to select pumps made from corrosion-resistant materials to ensure durability when transporting such fluids.

**Q4: How do I maintain my high pressure booster pump?**

A4: Regular maintenance includes checking seals, monitoring pressure levels, cleaning filters, and lubricating moving parts as recommended by the manufacturer.

**Q5: What is the typical lifespan of a high pressure booster pump?**

A5: The lifespan varies based on usage and maintenance but high-quality pumps can last several years with proper care, often exceeding 10 years.

8. Conclusion

Investing in a **high-quality high pressure booster pump** is a strategic decision that can significantly enhance operational efficiency and reduce costs in industrial applications. By understanding their working principles, recognizing the importance of efficiency, and considering the benefits of quality, businesses can make informed decisions that align with their operational goals. Selecting the right pump involves careful consideration of key features, and ensuring proper installation and maintenance practices is essential for maximizing performance. By prioritizing quality, companies can achieve long-term success and reliability in their fluid transportation systems.

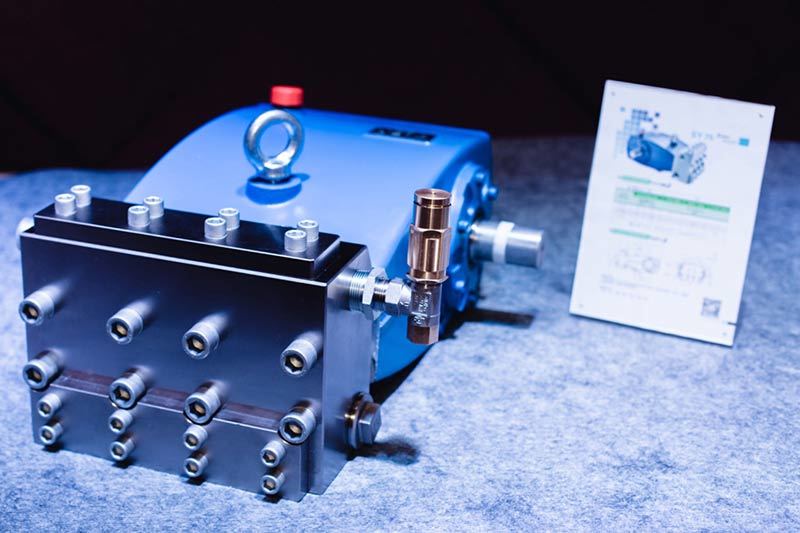

The 17th China International Powder Metallurgy and Hard Alloy Exhibition

The 2025 17th China International Powder Metallurgy and Hard Alloy Exhibition from March 10-12, 2025, at the Shanghai World Expo Exhibition and Convention Center, Hall H1, B425. We welcome guests to visit.

"Private custom" product design, reliable and durable finished products

"Private custom" like product design, reliable and durable finished products, professional and timely after-sales service. It is the "three basic concepts" that the company adheres to from the beginning until today ".

Experienced market research team, independent product development concept

We have experienced mature market research team, independent product research and development concept, professional design and manufacturing technology so that the company's products can be adjusted according to the specific requirements of customers timely design