Exploring the Advantages of the Newest High Pressure Plunger Pump

Table of Contents

- 1. Introduction to High Pressure Plunger Pumps

- 2. What is a Plunger Pump?

- 3. How Does the High Pressure Plunger Pump Work?

- 4. Advantages of the Newest High Pressure Plunger Pump

- 4.1 Improved Efficiency

- 4.2 Cost-Effectiveness

- 4.3 Durability and Reliability

- 4.4 Versatility in Applications

- 5. Key Applications of High Pressure Plunger Pumps

- 6. Maintenance Tips for Longevity

- 7. Frequently Asked Questions

- 8. Conclusion

1. Introduction to High Pressure Plunger Pumps

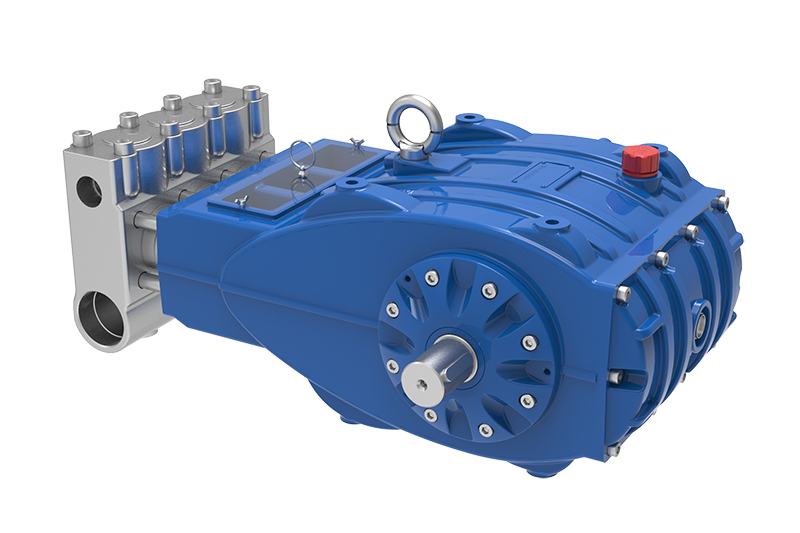

In the realm of industrial equipment, the **high pressure plunger pump** stands out as an essential component for various applications. Designed to handle high-pressure fluids, these pumps are characterized by their ability to deliver precise flow rates and withstand extreme operational conditions. As industries evolve, so do the technologies behind these pumps, leading to innovations that enhance their performance and reliability.

2. What is a Plunger Pump?

A **plunger pump** is a type of positive displacement pump that uses a reciprocating plunger to create pressure. Unlike centrifugal pumps, which rely on rotational motion, plunger pumps exert force through linear motion, making them ideal for high-pressure applications. They are commonly used in scenarios that require the transfer of viscous fluids, high-pressure cleaning, and injection systems.

3. How Does the High Pressure Plunger Pump Work?

The operation of a high pressure plunger pump involves several key components: the plunger, cylinder, valves, and a drive mechanism. When the plunger is pulled back, it creates a vacuum that draws fluid into the cylinder. As the plunger moves forward, it compresses the fluid and forces it through the outlet valves, generating high pressure. This cycle repeats rapidly, allowing for continuous fluid transfer.

4. Advantages of the Newest High Pressure Plunger Pump

4.1 Improved Efficiency

One of the most significant benefits of the newest high pressure plunger pumps is their **improved efficiency**. Advanced designs, including optimized plunger geometry and enhanced sealing technologies, reduce internal losses, enabling these pumps to deliver greater flow rates with less energy consumption. This efficiency translates into lower operational costs and reduced environmental impact.

4.2 Cost-Effectiveness

Investing in high pressure plunger pumps can lead to substantial **cost savings** over time. Their durability means fewer replacements and repairs, while their efficiency results in decreased energy bills. Additionally, because they can handle a wide range of fluids and pressures, businesses can consolidate their equipment needs, further saving on capital expenditures.

4.3 Durability and Reliability

The newest models of plunger pumps are engineered with **durability** in mind. Made from high-quality materials and equipped with advanced sealing systems, these pumps can operate in harsh conditions without compromising performance. Their reliable nature minimizes downtime and enhances overall productivity in industrial settings.

4.4 Versatility in Applications

High pressure plunger pumps are incredibly **versatile**. They are utilized in a variety of industries, including oil and gas, chemical processing, food and beverage, and water treatment. This adaptability makes them a valuable asset across different applications, from high-pressure cleaning to fluid transfer and chemical injection.

5. Key Applications of High Pressure Plunger Pumps

High pressure plunger pumps find their place in numerous applications, including but not limited to:

- **Hydraulic Systems**: These pumps provide the necessary pressure to operate hydraulic machinery, ensuring efficient performance.

- **Water Jet Cutting**: In this application, plunger pumps deliver ultra-high pressure water jets, allowing for precise cutting of materials.

- **Chemical Injection**: Industries often utilize plunger pumps to inject chemicals at high pressures for processes like water treatment and oil recovery.

- **High-Pressure Cleaning**: These pumps are essential for industrial cleaning tasks, offering efficient and effective cleaning solutions.

6. Maintenance Tips for Longevity

To maximize the lifespan and performance of high pressure plunger pumps, regular maintenance is crucial. Here are some essential maintenance tips:

- **Regular Inspections**: Conduct routine checks for wear on seals and valves, and replace components as necessary.

- **Fluid Quality**: Ensure the fluid used in the pump meets the manufacturer's specifications to prevent damage.

- **Lubrication**: Keep the pump properly lubricated according to the manufacturer's guidelines to reduce friction and wear.

- **Monitor Performance**: Keep an eye on pressure and flow rate to catch any deviations from normal operation early, allowing for prompt adjustments.

7. Frequently Asked Questions

What types of fluids can high pressure plunger pumps handle?

High pressure plunger pumps can handle a wide variety of fluids, including water, oil, and corrosive chemicals, depending on the materials used in their construction.

How do I choose the right plunger pump for my application?

Choosing the right pump involves considering factors such as required pressure, flow rate, the viscosity of the fluid, and the specific application. Consulting with a pump specialist can provide tailored recommendations.

What are the common issues faced with plunger pumps?

Common issues include seal wear, valve failure, and performance drops due to fluid contamination. Regular maintenance can help mitigate these problems.

Are high pressure plunger pumps energy-efficient?

Yes, modern high pressure plunger pumps are designed for energy efficiency, helping reduce operational costs while maintaining high performance.

Can plunger pumps be used for continuous operation?

Absolutely, high pressure plunger pumps are designed for continuous operation, making them ideal for industrial processes that require constant fluid transfer.

8. Conclusion

The newest high pressure plunger pumps represent a significant advancement in industrial pumping technology. With their impressive efficiency, cost-effectiveness, durability, and versatility, they are poised to become indispensable tools across various industries. By understanding their advantages and maintaining them properly, businesses can leverage these pumps to optimize operations, enhance productivity, and achieve substantial cost savings. As we continue to explore advancements in industrial equipment, high pressure plunger pumps will undoubtedly play a critical role in shaping the future of fluid management.

The 17th China International Powder Metallurgy and Hard Alloy Exhibition

The 2025 17th China International Powder Metallurgy and Hard Alloy Exhibition from March 10-12, 2025, at the Shanghai World Expo Exhibition and Convention Center, Hall H1, B425. We welcome guests to visit.

"Private custom" product design, reliable and durable finished products

"Private custom" like product design, reliable and durable finished products, professional and timely after-sales service. It is the "three basic concepts" that the company adheres to from the beginning until today ".

Experienced market research team, independent product development concept

We have experienced mature market research team, independent product research and development concept, professional design and manufacturing technology so that the company's products can be adjusted according to the specific requirements of customers timely design