Maximizing Efficiency: The Benefits of a Cheap Stainless Steel High Pressure Pump

Table of Contents

- 1. Introduction to High Pressure Pumps

- 2. What is a High Pressure Pump?

- 3. Benefits of Stainless Steel in Pump Manufacturing

- 4. Affordability and Cost Savings of Cheap Stainless Steel High Pressure Pumps

- 5. Applications in Various Industries

- 6. Maximizing Efficiency with High Pressure Pumps

- 7. Maintenance and Durability Considerations

- 8. Choosing the Right Cheap Stainless Steel High Pressure Pump

- 9. Frequently Asked Questions

- 10. Conclusion

1. Introduction to High Pressure Pumps

In modern industrial processes, **high-pressure pumps** play a crucial role in a wide array of applications. From chemical processing to water treatment, these pumps are designed to handle fluids at elevated pressures, ensuring efficient operation. Among various materials used in pump manufacturing, **stainless steel** stands out due to its strength, durability, and resistance to corrosion, making it an excellent choice for high-pressure environments. This article explores the numerous benefits of opting for cheap stainless steel high-pressure pumps, highlighting their potential to maximize efficiency and minimize costs.

2. What is a High Pressure Pump?

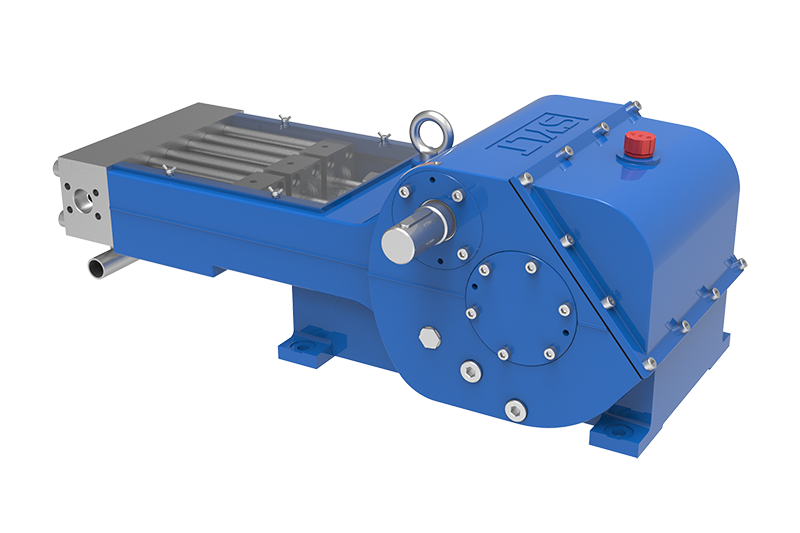

A **high-pressure pump** is specially designed to generate and maintain high fluid pressure in various systems. These pumps are capable of pumping fluids against significant resistance and can reach pressures well above 100 psi (pounds per square inch). High-pressure pumps are essential in applications where precise flow control, high efficiency, and reliability are required.

The construction of these pumps typically involves robust materials to withstand the stress associated with high pressure. **Stainless steel** is favored for its corrosion resistance and mechanical strength, essential for maintaining pump integrity over time.

3. Benefits of Stainless Steel in Pump Manufacturing

Choosing stainless steel for high-pressure pumps comes with numerous advantages:

3.1 Corrosion Resistance

Stainless steel is known for its superior resistance to corrosion, which is vital in industries dealing with harsh chemicals or varying environmental conditions. This resistance ensures a longer lifespan for the pump, reducing the frequency of replacements.

3.2 Strength and Durability

The inherent strength of stainless steel allows for the construction of pumps that can handle high pressures without compromising on performance. This durability translates to lower maintenance costs over time.

3.3 Ease of Maintenance

Stainless steel pumps are easier to clean and maintain due to their smooth surfaces. This quality is particularly beneficial in industries requiring strict hygiene standards, such as food and pharmaceuticals.

4. Affordability and Cost Savings of Cheap Stainless Steel High Pressure Pumps

When considering industrial equipment, cost is a significant factor. Cheap stainless steel high-pressure pumps provide an opportunity to acquire quality machinery without breaking the bank. Here’s how these pumps can lead to substantial cost savings:

4.1 Lower Initial Investment

Affordable stainless steel pumps are readily available, allowing businesses to invest in quality machinery at a lower cost. This initial savings can significantly impact a company's budget, especially for startups or small businesses.

4.2 Reduced Operating Costs

High-efficiency pumps tend to consume less energy during operation, leading to lower electricity bills. Additionally, their durability reduces the need for frequent replacements, which can further cut operational costs.

4.3 Improved Productivity

With reliable performance and minimal downtime, cheap stainless steel high-pressure pumps can enhance overall productivity. When machines operate efficiently, production processes can run smoothly, translating into higher output.

5. Applications in Various Industries

Cheap stainless steel high-pressure pumps find applications across a range of industries, showcasing their versatility and effectiveness:

5.1 Chemical Industry

In the chemical industry, high pressure pumps are used for transferring corrosive fluids. The corrosion-resistant nature of stainless steel makes it ideal for handling chemicals without degrading.

5.2 Water Treatment

High-pressure pumps are essential in water treatment facilities, where they are used to move water through filtration systems and other processes. Their reliability ensures clean water supply and treatment.

5.4 Food and Beverage Industry

In food processing, stainless steel pumps are crucial for transporting liquids while meeting strict hygiene standards. Their ease of maintenance and cleaning aligns with food safety regulations.

5.5 Oil and Gas Industry

High-pressure pumps play a vital role in the oil and gas sector, where they are used for hydraulic fracturing and transporting crude oil. Their robustness withstands the harsh conditions of this industry.

6. Maximizing Efficiency with High Pressure Pumps

To maximize efficiency in industrial operations, consider the following strategies when utilizing cheap stainless steel high-pressure pumps:

6.1 Regular Maintenance

Implementing a regular maintenance schedule helps identify potential issues before they escalate, ensuring that pumps operate at peak efficiency. Cleaning and inspecting pump components reduces the risk of unexpected failures.

6.2 Monitor Operational Parameters

Keeping track of operational parameters such as pressure, flow rate, and temperature enables operators to detect anomalies early. This monitoring can prevent operational inefficiencies and prolong pump life.

6.3 Optimize System Design

Designing a system that minimizes bends and turns in piping can enhance pump efficiency. A well-designed system reduces the workload on pumps and improves fluid flow.

7. Maintenance and Durability Considerations

Maintaining cheap stainless steel high-pressure pumps is straightforward, yet critical for ensuring long-term durability. Here are key maintenance practices:

7.1 Routine Inspections

Conducting routine inspections helps spot wear and tear in pump components. This proactive approach can prevent breakdowns and costly repairs.

7.2 Lubrication

Proper lubrication of moving parts reduces friction and wear, ensuring smoother operations. Always follow the manufacturer's guidelines for lubrication intervals and types of lubricants to use.

7.3 Cleaning

Regular cleaning of pumps and associated piping systems removes build-up that can hinder performance. For stainless steel pumps, using non-corrosive cleaning agents is advisable to maintain surface integrity.

8. Choosing the Right Cheap Stainless Steel High Pressure Pump

Selecting the right high-pressure pump involves evaluating several factors:

8.1 Assess Your Application Needs

Understand the specific requirements of your application, including required pressure, flow rate, and the type of fluids being pumped. This assessment ensures that you choose a pump that meets operational demands.

8.2 Research and Compare Models

Conduct thorough research on various pump models, focusing on specifications, reliability, and user reviews. Comparing different options helps in making an informed decision.

8.3 Consult with Experts

Consulting with industry experts or pump manufacturers can provide valuable insights into making the best choice for your needs. Their experience can guide you towards the most effective solution.

9. Frequently Asked Questions

9.1 What are the typical uses of high-pressure pumps?

High-pressure pumps are used in various applications, including chemical processing, water treatment, food and beverage production, and oil and gas extraction. They are ideal for situations requiring elevated fluid pressure.

9.2 How do stainless steel high-pressure pumps compare to other materials?

Stainless steel pumps offer superior corrosion resistance, strength, and durability compared to other materials. They are also easier to maintain and clean, making them suitable for demanding industrial applications.

9.3 What maintenance is required for high-pressure pumps?

Routine maintenance includes inspections, lubrication of moving parts, and regular cleaning. Following the manufacturer’s maintenance guidelines ensures optimal performance and longevity.

9.4 Are cheap high-pressure pumps reliable?

Cheap stainless steel high-pressure pumps can be reliable if sourced from reputable manufacturers. It's essential to research and verify the quality of the pump before purchasing.

9.5 How can I improve the efficiency of my high-pressure pump system?

To enhance efficiency, implement regular maintenance, monitor operational parameters, and optimize your system's design to minimize resistance and ensure smooth fluid flow.

10. Conclusion

The utilization of cheap stainless steel high-pressure pumps can significantly enhance efficiency across various industrial applications. With their cost-effectiveness, durability, and reliability, these pumps provide businesses with the opportunity to improve their operational capabilities while maintaining budgetary constraints. By investing in quality stainless steel high-pressure pumps, industries can leverage increased productivity and reduced operational costs, making them an essential component of modern manufacturing and processing environments.

The 17th China International Powder Metallurgy and Hard Alloy Exhibition

The 2025 17th China International Powder Metallurgy and Hard Alloy Exhibition from March 10-12, 2025, at the Shanghai World Expo Exhibition and Convention Center, Hall H1, B425. We welcome guests to visit.

"Private custom" product design, reliable and durable finished products

"Private custom" like product design, reliable and durable finished products, professional and timely after-sales service. It is the "three basic concepts" that the company adheres to from the beginning until today ".

Experienced market research team, independent product development concept

We have experienced mature market research team, independent product research and development concept, professional design and manufacturing technology so that the company's products can be adjusted according to the specific requirements of customers timely design