Why Classy High Pressure Plunger Pumps Are Essential for Industrial Applications

Table of Contents

- 1. Introduction to High Pressure Plunger Pumps

- 2. Understanding Plunger Pumps: Mechanism and Design

- 3. Advantages of High Pressure Plunger Pumps in Industrial Settings

- 4. Applications of High Pressure Plunger Pumps Across Industries

- 5. Key Features of Classy High Pressure Plunger Pumps

- 6. Choosing the Right Plunger Pump for Your Needs

- 7. Maintenance and Reliability of High Pressure Plunger Pumps

- 8. Future Trends in High Pressure Pump Technology

- 9. Frequently Asked Questions

- 10. Conclusion

1. Introduction to High Pressure Plunger Pumps

In the realm of industrial applications, **high pressure plunger pumps** play an indispensable role. These pumps are engineered to handle various challenging tasks, from fluid transfer to precise dosing. Their ability to maintain consistent pressure and flow rates makes them a top choice for many industries. High pressure plunger pumps are particularly valued for their efficiency and reliability, making them key components in operations that require precise liquid handling.

2. Understanding Plunger Pumps: Mechanism and Design

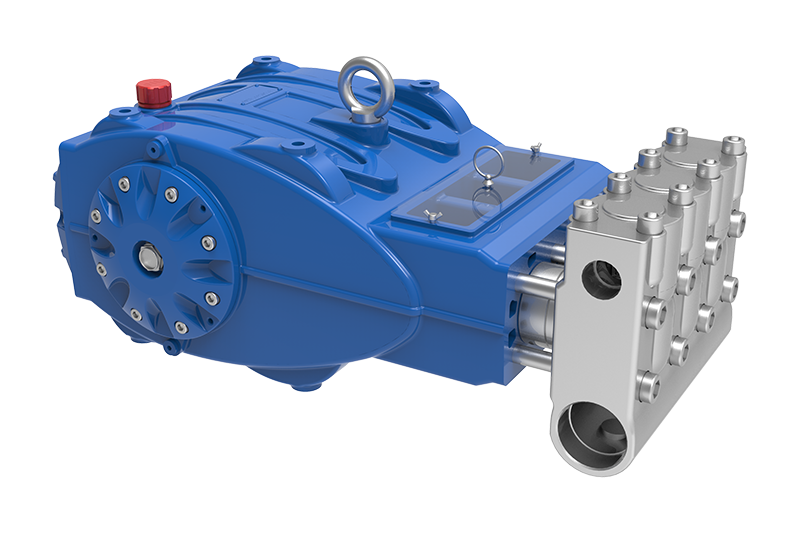

High pressure plunger pumps operate based on a simple yet effective mechanism. Typically, they consist of a piston or plunger that moves back and forth within a cylinder to create pressure. This design allows for the pump to handle a wide range of fluids, including those that are viscous or contain solids. Their robust construction ensures durability, which is essential for high-stress industrial environments.

**Key components** of a plunger pump include:

- **Plunger:** The moving part that generates pressure by displacing fluid.

- **Cylinder:** Houses the plunger and contains the fluid.

- **Check Valves:** Allow fluid to enter and exit the pump, ensuring one-way flow.

- **Drive Mechanism:** Powers the plunger's movement, typically through a motor.

Understanding these components is crucial for optimizing pump performance and ensuring longevity.

3. Advantages of High Pressure Plunger Pumps in Industrial Settings

Investing in classy high pressure plunger pumps comes with many advantages that can significantly enhance industrial operations:

3.1 Exceptional Efficiency

High pressure plunger pumps are designed to operate at high efficiencies, which translates to reduced energy consumption and lower operational costs. Their capability to maintain consistent flow rates at various pressures ensures that processes run smoothly without interruptions.

3.2 Versatility in Applications

These pumps can handle a variety of fluids, including corrosive, viscous, and abrasive liquids. This versatility makes them applicable in diverse industries such as food and beverage, oil and gas, and chemical processing.

3.3 High Pressure Capability

As their name suggests, high pressure plunger pumps can generate significant pressure, making them suitable for applications requiring forceful liquid movement. This capability is essential in processes like hydraulic fracturing and high-pressure cleaning.

3.4 Durability and Longevity

Classy high pressure plunger pumps are built to last. Their robust construction minimizes wear and tear, ensuring they can withstand harsh operating conditions. Regular maintenance can further extend their lifespan.

4. Applications of High Pressure Plunger Pumps Across Industries

High pressure plunger pumps are employed in various industrial sectors, each benefiting from the unique features these pumps offer.

4.1 Oil and Gas Industry

In the oil and gas sector, plunger pumps are used for hydraulic fracturing, delivering the necessary fluids at high pressure to fracture rock formations and facilitate oil extraction.

4.2 Chemical Processing

Chemical manufacturing often requires precise dosing of reactive substances. High pressure plunger pumps provide the accuracy and reliability needed for handling corrosive chemicals safely.

4.3 Water Treatment

Plunger pumps are utilized in water treatment facilities to transport and pressurize water effectively, ensuring quality control and compliance with environmental standards.

4.4 Food and Beverage Industry

In food processing, these pumps are essential for transporting liquids like syrups, sauces, and other viscous products while maintaining hygienic standards.

5. Key Features of Classy High Pressure Plunger Pumps

When selecting a high pressure plunger pump, it is crucial to consider several vital features that contribute to its performance.

5.1 Flow Rate and Pressure Ratings

Understanding the specific flow rates and pressure ratings required for your application is fundamental. High pressure plunger pumps are available with various configurations to meet diverse needs.

5.2 Material Construction

The materials used in constructing a plunger pump determine its compatibility with different fluids. Stainless steel and specialized alloys are commonly used to ensure durability against corrosion and wear.

5.3 Seal and Valve Quality

Quality seals and valves are essential for preventing leaks and maintaining system pressure. Choosing pumps with high-quality components can significantly influence performance.

6. Choosing the Right Plunger Pump for Your Needs

Selecting the right high pressure plunger pump involves careful consideration of several factors:

6.1 Identify Application Requirements

Determine the specific requirements of your application, including the type of fluid being pumped, required flow rate, and pressure levels.

6.2 Evaluate Pump Types

Familiarize yourself with different types of plunger pumps available in the market. Some may be more suited for specific applications than others.

6.3 Consult with Experts

Engaging with pump professionals can provide valuable insights into which pump is best suited for your operations, taking into account factors like efficiency, cost, and maintenance.

7. Maintenance and Reliability of High Pressure Plunger Pumps

Regular maintenance is vital to ensure the reliability and longevity of high pressure plunger pumps. Implementing a structured maintenance program can help identify potential issues before they lead to failure.

7.1 Regular Inspections

Conduct routine inspections to check for wear and tear on critical components, including seals, check valves, and the plunger itself.

7.2 Lubrication

Ensure that moving parts are adequately lubricated to minimize friction and wear. Proper lubrication is crucial for maintaining performance.

7.3 Troubleshooting Common Issues

Familiarize yourself with common problems that can affect plunger pump performance, such as cavitation and pressure fluctuations. Understanding these issues can lead to quicker resolutions and less downtime.

8. Future Trends in High Pressure Pump Technology

The future of high pressure plunger pumps is promising, with several trends shaping their evolution:

8.1 Innovative Materials

Advancements in material science are leading to the development of more durable and lightweight materials, enhancing pump performance and efficiency.

8.2 Smart Technology Integration

The integration of smart technology and IoT (Internet of Things) capabilities is becoming increasingly common. This allows for real-time monitoring of pump performance and predictive maintenance strategies.

8.3 Sustainability Focus

As industries move towards sustainable practices, the demand for energy-efficient and environmentally friendly pumping solutions is on the rise. High pressure plunger pumps are being designed with these considerations in mind.

9. Frequently Asked Questions

9.1 What is the typical lifespan of a high pressure plunger pump?

The lifespan of a high pressure plunger pump can vary based on usage and maintenance, but with proper care, it can last several years.

9.2 How do I know what size pump I need?

Sizing a pump depends on the application’s flow rate and pressure requirements. Consulting with a pump specialist can help ensure you choose the right size.

9.3 Can high pressure plunger pumps handle abrasive fluids?

Yes, many high pressure plunger pumps are designed to handle abrasive fluids, but it's essential to select a pump specifically rated for this type of application.

9.4 What maintenance is required for high pressure plunger pumps?

Regular maintenance includes inspections, lubrication, and replacing worn components like seals and check valves.

9.5 Are there energy-efficient options available for high pressure plunger pumps?

Yes, many manufacturers offer energy-efficient high pressure plunger pumps designed to reduce operational costs while maintaining performance.

10. Conclusion

Classy high pressure plunger pumps are essential assets in various industrial applications. Their efficiency, versatility, and durability make them a preferred choice for handling challenging tasks across multiple sectors. By understanding their mechanism, advantages, and key features, industrial operators can make informed decisions that enhance their processes and productivity. With continuous advancements in technology and materials, the future of high pressure plunger pumps is set to become even more promising, offering innovative solutions for modern industrial challenges. Investing in high-quality plunger pumps is not just a smart choice; it is a necessity for sustaining operational excellence in today’s competitive landscape.

The 17th China International Powder Metallurgy and Hard Alloy Exhibition

The 2025 17th China International Powder Metallurgy and Hard Alloy Exhibition from March 10-12, 2025, at the Shanghai World Expo Exhibition and Convention Center, Hall H1, B425. We welcome guests to visit.

"Private custom" product design, reliable and durable finished products

"Private custom" like product design, reliable and durable finished products, professional and timely after-sales service. It is the "three basic concepts" that the company adheres to from the beginning until today ".

Experienced market research team, independent product development concept

We have experienced mature market research team, independent product research and development concept, professional design and manufacturing technology so that the company's products can be adjusted according to the specific requirements of customers timely design