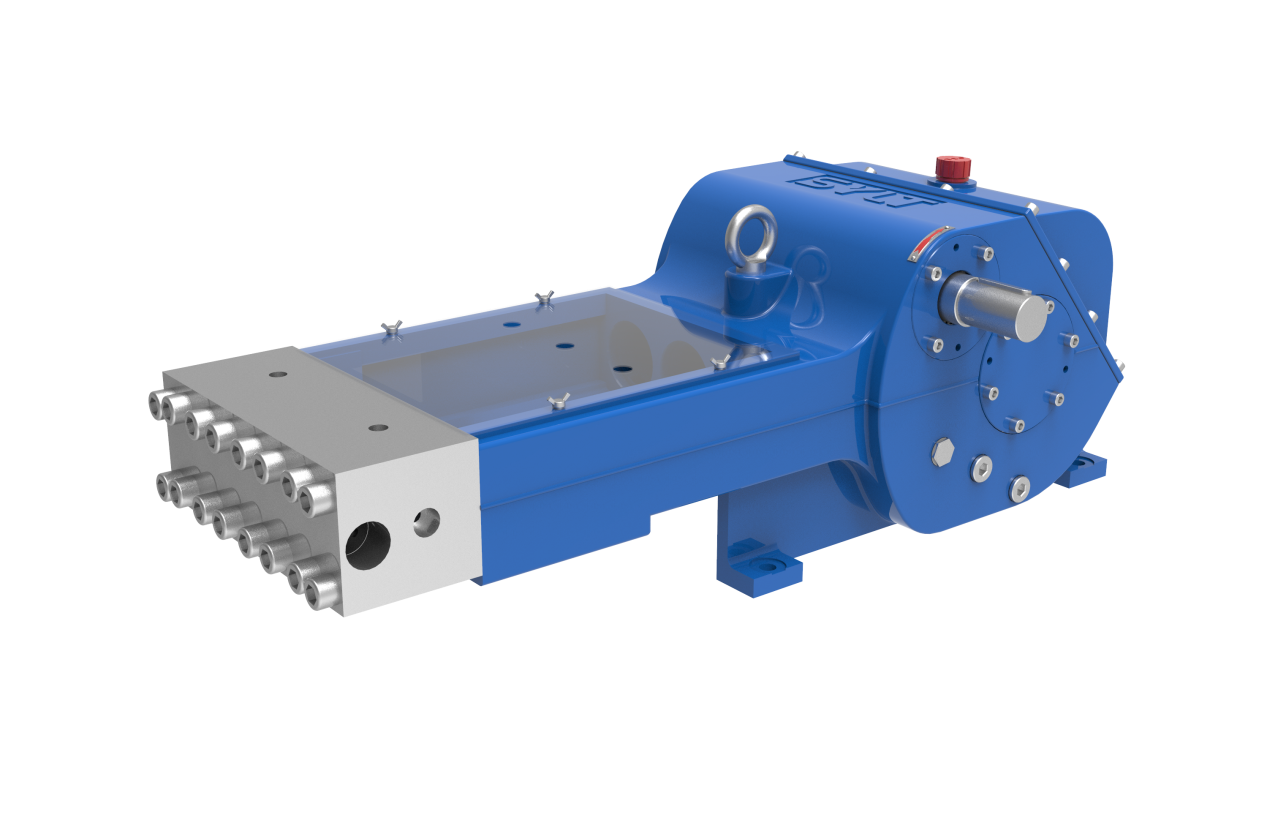

Advantages and Disadvantages of Horizontal High-Pressure Plunger Pumps

I. Advantages

1. High Operational Stability

- Structural Advantages: The horizontal layout lowers the center of gravity, provides even bearing support, reduces vibration during operation, and is suitable for high-speed, high-power applications (such as oil fracturing pumps).

- Impact Resistance: It can withstand continuous impacts of high pressure (100~150 MPa) and high flow rate (100~3000 L/min), suitable for ultra-high-pressure water jetting, oilfield fracturing, and other harsh working conditions.

2. Strong Medium Adaptability

- High-Viscosity Media: The horizontal flow path design can effectively transport high-viscosity liquids (such as asphalt, resin), avoiding blockages caused by excessive flow resistance.

- Media Containing Particles: Suitable for handling slurries, ore pulps, or chemical slurries containing solid particles; some models use carbide valve groups or ceramic coatings to improve wear resistance.

3. Convenient Maintenance

- Horizontally Split Structure: The pump cover can be quickly disassembled, facilitating the replacement of valve groups, seals, or plungers, and reducing downtime.

- Easy Accessibility: Key components such as bearings and couplings are exposed, making daily inspection and lubrication easier.

4. Expandability and Flexibility

- Multi-Pump Unit Design: Multiple pump heads (such as three-cylinder or five-cylinder pump units) can be connected in parallel to meet high flow rate requirements for large-discharge scenarios such as oil fracturing.

- Pipeline Layout Compatibility: Horizontal installation allows for direct connection to the factory's horizontal pipeline system, reducing the need for elbows or reducers.

5. Long Lifespan Design (Under Specific Conditions)

- High-Pressure Resistant Materials: Using tungsten carbide plungers, ceramic-coated cylinder liners, etc., to maintain stable lifespan even under ultra-high-pressure conditions.

- Modular Replacement: Worn parts (such as valve groups) can be replaced individually, reducing overall maintenance costs.

II. Disadvantages

1. Large Footprint

- Space Requirements: The horizontal layout requires a larger installation space and is unsuitable for confined environments (such as vehicle-mounted equipment, ship cabins).

- Foundation Requirements: Requires space for horizontal pipeline connections, limiting the flexibility of the factory layout to some extent.

2. Limited Suction Capacity

- Cavitation Risk: The suction head is generally less than 5 meters, requiring inlet pressure or a booster tank, increasing system complexity.

- Sensitive to Liquid Vaporization: At high temperatures, insufficient suction head can easily lead to liquid vaporization, requiring additional cooling or pressurization measures.

3. Wear Issues

- Unilateral Wear: When the plunger moves horizontally, it is affected by gravity, which easily leads to unilateral wear of the cylinder liner. Regular adjustments or part replacements are needed.

- Maintenance Frequency: When operating in media containing particles, wear is aggravated, and the maintenance cycle may be shortened (e.g., mine slurry pumps require inspection every 3 months).

4. Higher Initial Cost

- Structural Complexity: Requires reinforcement of bearings, seals, and support structures to withstand high pressure and radial loads; manufacturing costs are higher than vertical pumps.

- Material Costs: Ultra-high-pressure models require special alloys or ceramic coatings, further increasing costs.

5. Relatively High Energy Consumption

- Flow Path Resistance: The flow resistance of liquids in horizontal flow paths is greater under high pressure; energy efficiency is slightly lower than vertical pumps (especially in low-viscosity media).

III. Typical Application Scenarios (Highlighting Advantages and Disadvantages)

1. Oil Fracturing Pumps (Advantages: Ultra-high pressure, high flow rate; Disadvantages: High cost)

- Uses a horizontal five-cylinder pump unit with a pressure of 150 MPa, but requires frequent maintenance for plunger wear issues.

2. Mine Drainage Pumps (Advantages: Particle resistance; Disadvantages: High maintenance frequency)

- Excellent performance in handling muddy wastewater containing sand, but requires quarterly cleaning of flow paths and replacement of worn valve groups.

3. Chemical Process Pumps (Advantages: Corrosion resistance; Disadvantages: Suction head limitations)

- When transporting corrosive resins, Hastelloy valve groups are used, but an inlet booster pump is required.

IV. Directions for Technological Improvement (Mitigating Disadvantages)

1. Material Upgrades:

- Using diamond-coated plungers or silicon carbide sealing rings to reduce wear and media corrosion.

2. Intelligent Monitoring:

- Installing vibration sensors to monitor the degree of wear in real time for predictive maintenance and extended lifespan.

3. Modular Design:

- Quickly replace valve groups and plunger kits to reduce downtime (e.g., maintenance time for a certain model is reduced from 8 hours to 2 hours).

V. Summary

Applicable Scenarios: Oil fracturing, mine drainage, chemical processes, and other industrial scenarios involving high-pressure, high-viscosity, or impurity-containing media.

Suggestions for Avoiding Pitfalls: If space is limited or a high suction head is required, prioritize vertical pumps; if the medium is clean and the pressure requirements are moderate, vertical pumps are more cost-effective.

The 17th China International Powder Metallurgy and Hard Alloy Exhibition

The 2025 17th China International Powder Metallurgy and Hard Alloy Exhibition from March 10-12, 2025, at the Shanghai World Expo Exhibition and Convention Center, Hall H1, B425. We welcome guests to visit.

"Private custom" product design, reliable and durable finished products

"Private custom" like product design, reliable and durable finished products, professional and timely after-sales service. It is the "three basic concepts" that the company adheres to from the beginning until today ".

Experienced market research team, independent product development concept

We have experienced mature market research team, independent product research and development concept, professional design and manufacturing technology so that the company's products can be adjusted according to the specific requirements of customers timely design