Discover the Top Features of the Best High Pressure Pumps for Industrial Applications

High-pressure pumps are essential components in various industrial applications, from manufacturing processes to oil and gas extraction. When selecting the right high-pressure pump, understanding its key features can significantly impact operational efficiency and cost-effectiveness. This article explores the top features that define the best high-pressure pumps, ensuring you make an informed choice for your business needs.

Table of Contents

- Understanding High Pressure Pumps

- Key Technical Features of High Pressure Pumps

- Pump Design and Materials

- Performance Efficiency Metrics

- Maintenance Requirements for Longevity

- Applications of High Pressure Pumps

- Choosing the Right Pump for Your Needs

- Frequently Asked Questions

Understanding High Pressure Pumps

High-pressure pumps are designed to generate fluid pressure significantly greater than atmospheric pressure. They are used to move liquids through pipelines, assist in hydraulic systems, and perform various industrial tasks. Understanding their functionality is crucial for selecting an appropriate model for specific applications.

How High Pressure Pumps Work

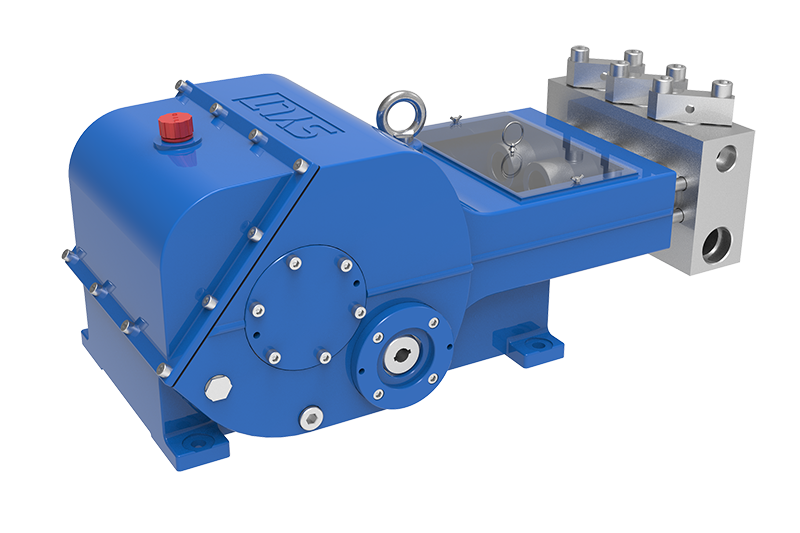

High-pressure pumps operate by converting mechanical energy into hydraulic energy. This process involves the use of a motor or engine, which drives the pump's internal mechanisms to compress the liquid, thereby increasing its pressure. The primary types of high-pressure pumps include positive displacement pumps and centrifugal pumps, each offering distinct advantages based on application requirements.

Key Technical Features of High Pressure Pumps

Several technical features distinguish high-pressure pumps, affecting their performance and suitability for various industries. Understanding these features will help in evaluating different models.

Pressure Ratings

One of the most crucial specifications is a pump's pressure rating, typically measured in bars or PSI. The best high-pressure pumps can handle pressures exceeding 5000 PSI, making them suitable for demanding applications like hydraulic fracturing and pressure testing.

Flow Rate

Flow rate, measured in gallons per minute (GPM) or liters per minute (LPM), indicates how much fluid a pump can move within a given timeframe. Selecting a pump with the right flow rate is essential to ensure it meets the operational demands of your application.

Efficiency Ratings

Efficiency in high-pressure pumps is critical for minimizing energy costs and maximizing output. Look for pumps with high-efficiency ratings, which indicate that a greater percentage of the input energy converts into hydraulic energy.

Pump Design and Materials

The design and materials used in high-pressure pumps play a significant role in their durability and performance. High-quality materials can resist corrosion and wear, extending the pump's lifespan and reducing maintenance costs.

Material Types

Common materials include stainless steel, cast iron, and various alloys. Stainless steel is particularly favored for its resistance to corrosion, making it ideal for applications involving aggressive chemicals.

Compact and Modular Designs

Modern high-pressure pumps often feature compact and modular designs that facilitate easier installation and maintenance. A modular design allows for the quick replacement of components, minimizing downtime during maintenance.

Performance Efficiency Metrics

Performance efficiency is a vital aspect of selecting high-pressure pumps. Beyond basic specifications, understanding a pump's operational metrics can aid in making the best choice.

Energy Consumption

Energy consumption directly impacts operational costs. High-efficiency models reduce energy usage while maintaining performance, making them more cost-effective in the long run.

Noise Levels

Noise levels can be a concern in industrial environments. Pumps designed with noise-dampening technology can provide a quieter operation, improving workplace conditions.

Maintenance Requirements for Longevity

Regular maintenance is essential to ensure high-pressure pumps operate efficiently and last longer. Understanding the maintenance needs can help prevent unexpected downtime.

Routine Inspections

Conducting routine inspections of seals, bearings, and other components can help identify potential issues before they escalate. Regular checks can extend the life of the pump and optimize performance.

Lubrication Needs

Proper lubrication is vital for minimizing friction and wear between moving parts. Regularly checking and replenishing lubrication reduces the risk of mechanical failure.

Applications of High Pressure Pumps

High-pressure pumps are utilized across various industries, demonstrating their versatility and importance. Here’s a look at some common applications.

Manufacturing Processes

In manufacturing, high-pressure pumps are used for material processing, spray painting, and cleaning operations. Their ability to deliver high-pressure fluids enhances efficiency in production lines.

Oil and Gas Industry

In the oil and gas sector, these pumps facilitate hydraulic fracturing and enhanced oil recovery, providing the necessary pressure to extract resources from deep underground.

Water Treatment Systems

High-pressure pumps play a critical role in water treatment, assisting in processes such as reverse osmosis and filtration, ensuring clean and safe water supply.

Choosing the Right Pump for Your Needs

Selecting the right high-pressure pump involves considering various factors, including application requirements, budget constraints, and operational conditions.

Assessing Application Needs

Evaluate the specific requirements of your application, including desired pressure, flow rate, and the type of fluid being pumped. Understanding these needs will help narrow down your options.

Cost vs. Quality

While budget is essential, focusing solely on the initial cost can lead to higher long-term expenses due to maintenance and inefficiency. Investing in a quality high-pressure pump can save money over time.

Frequently Asked Questions

1. What is the average lifespan of a high-pressure pump?

The lifespan of a high-pressure pump can vary widely based on usage and maintenance but typically ranges from 5 to 15 years.

2. How often should high-pressure pumps be serviced?

Routine maintenance is recommended every 6 to 12 months, depending on the pump's operational environment and usage frequency.

3. Can high-pressure pumps handle abrasive fluids?

Some models are designed specifically for abrasive fluids, featuring materials and coatings that resist wear and tear.

4. What types of fluids can high-pressure pumps handle?

High-pressure pumps can handle various fluids, including water, oils, and chemicals. It's crucial to match pump materials with the fluid's properties.

5. Are there any energy-efficient high-pressure pump options?

Yes, many manufacturers offer energy-efficient models that reduce energy consumption while maintaining high performance, thereby lowering operational costs.

Conclusion

In summary, choosing the best high-pressure pump for your industrial application requires a thorough understanding of its features, performance metrics, and maintenance needs. By focusing on key technical specifications, design materials, and operational requirements, we empower ourselves to make informed decisions that enhance efficiency and reduce costs. As industries continue to evolve, staying informed about the latest advancements in high-pressure pump technology will ensure optimal performance and reliability for years to come.

The 17th China International Powder Metallurgy and Hard Alloy Exhibition

The 2025 17th China International Powder Metallurgy and Hard Alloy Exhibition from March 10-12, 2025, at the Shanghai World Expo Exhibition and Convention Center, Hall H1, B425. We welcome guests to visit.

"Private custom" product design, reliable and durable finished products

"Private custom" like product design, reliable and durable finished products, professional and timely after-sales service. It is the "three basic concepts" that the company adheres to from the beginning until today ".

Experienced market research team, independent product development concept

We have experienced mature market research team, independent product research and development concept, professional design and manufacturing technology so that the company's products can be adjusted according to the specific requirements of customers timely design